Alloys

Browse Alloys for the Material That Best Fits Your Application

MetalTek brings practical expertise in hundreds of alloy grades. This means that our customers get the material properties that they need to make their products perform better in the world's most demanding applications. Please browse the alloys displayed below or use the search and filter options to identify the exact grade that you need.

For more information about a specific alloy or its application, contact us or consider a TekSession. You can also download our Alloy Guide.

Search

Alloys

Alloy Cast Number

MetalTek Grade

Related Blogs

How To Choose a Metal Casting Supplier for the Petrochemical Industry

304 vs. 316 Stainless Steel: Which One Is Better?

Will Aluminum Rust or Corrode?

The 101 On Thermal Conductivity In Metal Alloys

A Guide to Different Types of Bronze Alloys

What Is Low Alloy Steel?

Specialized Metal Alloys For Pulp & Paper Applications

Tooling And Forming Dies: Tips For Selecting The Best Alloy For Your Application

What Are Tool Steel Alloys?

Material Applications: Alternative Corrosion Resistant Materials

Nickel: Where Does It Come From?

Precipitation Hardening Stainless Steel

Hi-Ho Silver: The History Of Silver

The History of Copper

What Makes It Stainless?

What Is Duplex Stainless Steel?

It’s Still The Bronze Age

Bearium Alloys

What Are Cobalt-Based Metals?

Nickel-Based Alloys

Copper Based Alloys – An Overview

What Are Ferrous Alloys?

What Is Tin Bronze?

What Is Aluminum Bronze? Is Aluminum Bronze An Alloy?

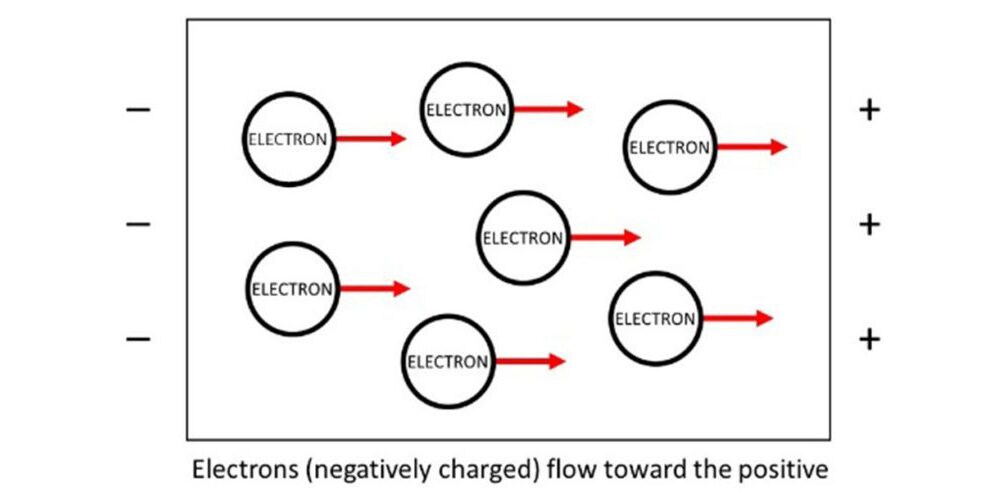

What Is Conductivity in Metals?

What Is Non-Ferrous Metal? What are Non-Ferrous metals?

Alloy Grade UNS: ALLOY 86 – Duplex Stainless Steel

Cast UNS:

Cast Grade:

Cast ASTM:

Military/ASM:

Alloy Grade UNS: CD3MN, 4A – Seawater Corrosion Resistance

Cast UNS: J92205

Cast Grade: CD3MN, 4A

Cast ASTM: A890, A995

Military/ASM:

Alloy Grade UNS: CD3MWCuN, 6A – Duplex Stainless Steel

Cast UNS: J93380

Cast Grade: CD3MWCuN, 6A

Cast ASTM: A890, A995

Military/ASM:

Alloy Grade UNS: CD4MCu,1A – Metal Alloy

Cast UNS: J93370

Cast Grade: CD4MCu,1A

Cast ASTM: A890, A995

Military/ASM:

Alloy Grade UNS: CD4MCuN, 1B – Seawater Corrosion Resistance

Cast UNS: J93372

Cast Grade: CD4MCuN, 1B

Cast ASTM: A890, A995

Military/ASM:

Alloy Grade UNS: CE3MN, 5A – Duplex Stainless Steel

Cast UNS: J93404

Cast Grade: CE3MN, 5A

Cast ASTM: A890, A995

Military/ASM:

Alloy Grade UNS: CE8MN, 2A – Stronger than common Stainless Steel

Cast UNS: J93345

Cast Grade: CE8MN, 2A

Cast ASTM: A890, A995

Military/ASM:

Alloy Grade UNS: J32550 – Seawater Corrosion Resistance

Cast UNS: J32550

Cast Grade:

Cast ASTM:

Military/ASM: