Metallurgy & Engineering

Integrated Expertise Of More Than 100 Metallurgists And Engineers

MetalTek’s integrated approach to manufacturing is led by the alloy and process expertise of more than 100 metallurgists and engineers across multiple locations. Our integrated approach allows us to partner with our customers to make their products perform better in the world's most demanding applications. Our vast team of experts coordinate each step of the way. Your metal casting project will involve metallurgists and engineers working side by side to ensure the highest quality outcome.

Contact us for more information about our integrated alloy and manufacturing process expertise, or consider a TekSession. You can also visit our blog or browse our hundreds of available alloys for the material properties that best fit your application.

What Is Metallurgy?

Metallurgy involves purifying metals and forming alloys, metals formed by combining two or more metallic elements to capture specific properties. MetalTek metallurgists help customers select specific alloys to improve product performance, especially in high-heat, high-wear, and high-corrosion environments. Metallurgy engineering is at the core of MetalTek’s expertise. Our metallurgists have 100s of combined years of experience. We offer a comprehensive solution from start to finish for a customer's project.

Value Engineering

Value engineering is a systematic approach to analyzing manufacturing costs and related processes. Metallurgists and engineers at MetalTek work together and directly with customers to understand specific product needs. Then, our team of experts makes recommendations for the metallurgy and manufacturing process that achieves the highest possible product quality at the lowest possible cost. Metal casting projects can be expensive and time-consuming, hence the value engineering approach to combat these common concerns.

Advantages of our integrated metallurgy and value engineering approach include:

-

Market expertise: Our metallurgists and engineers help customers meet the strictest levels of compliance through hundreds of years of combined experience in demanding, high-specification markets such as aerospace, defense, and petrochemical.

-

Conversion assistance: MetalTek engineers help customers reduce costs and improve product quality by converting to metal castings from alternative processes such as fabrications or forgings.

-

Metallurgy/Alloy selection: MetalTek routinely pours over 450 ferrous and non-ferrous alloys, including proprietary grades. Our metallurgy expertise allows customers to choose alloys that meet the most demanding product requirements.

-

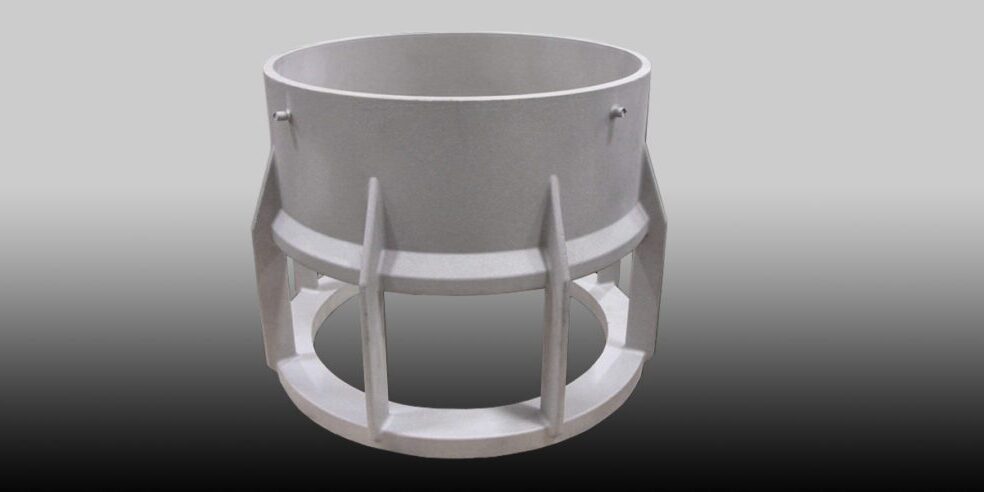

Casting process selection: From centrifugal casting to sand casting to investment casting, our engineers use the latest computer modeling tools to help customers determine which casting processes best fit their specific product needs.

-

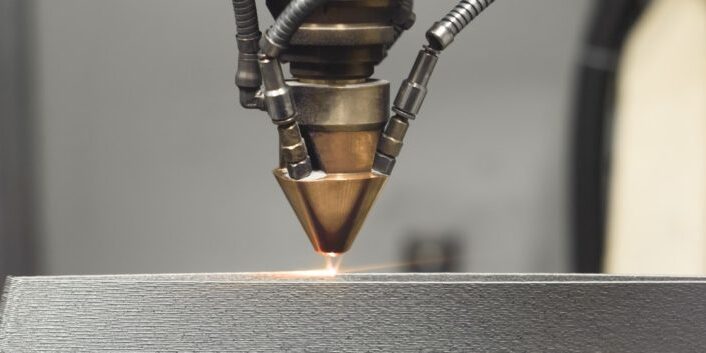

Rapid prototyping: MetalTek can significantly reduce cost and time to market through several different rapid prototyping technologies. Methods such as 3D printing, Direct Mold Milling, or stereolithography (SLA)can virtually eliminate lead times associated with standard tooling for prototyping or low volumes.

-

TekSession Training: Our metallurgy and process engineers conduct on-site or virtual trainingon casting or alloy selection, conversions from fabrications or forgings, product design, or other topics tailored to specific needs.

Contact us for more information about our integrated metallurgy and manufacturing process expertise , or consider a TekSession. You can also visit our blog or browse our hundreds of available alloys for the material properties that best fit your application.