Sandusky International

leader in paper suction roll shells and other centrifugal castings

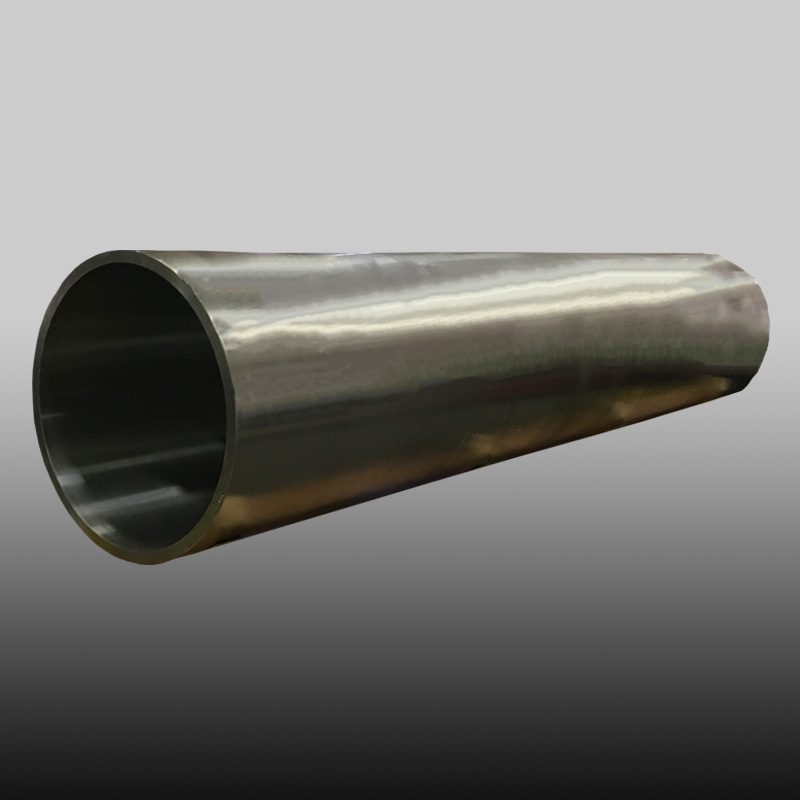

Customers have been partnering with Sandusky International for decades because of our unique ability to produce centrifugal castings in very large sizes – up to 432" (11 m) in length. Sandusky pioneered the centrifugal casting process over a century ago and offers unparalleled flexibility in dimensions, composition, and properties. We leverage unique tooling capabilities, large capacities, and unparalleled centrifugal technical expertise. Sandusky International can do more for customers, with steel and countless metals, than anyone else.

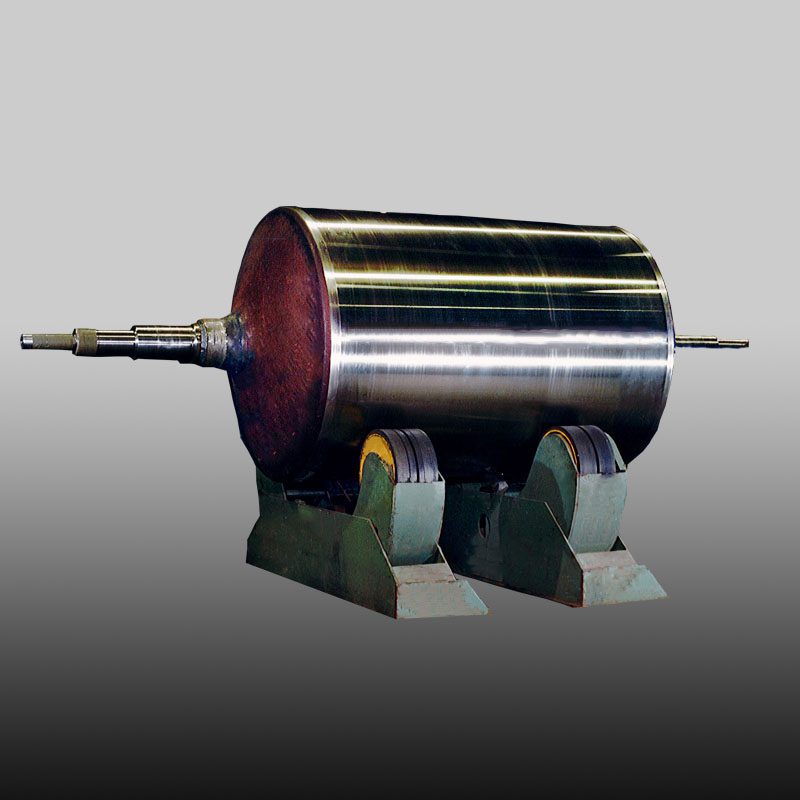

Papermaking Machinery

Sandusky International has been the world leader in centrifugally cast paper roll shell manufacturing and supply since pioneering the process more than a century ago. Customers rely on us because we are the only fully integrated suction roll shell manufacturer in the world.

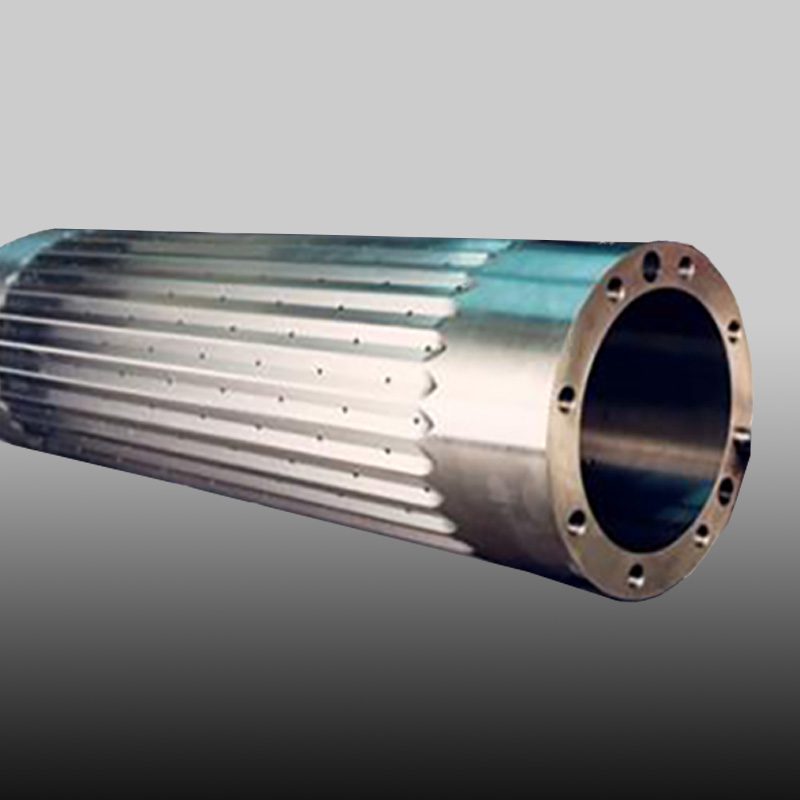

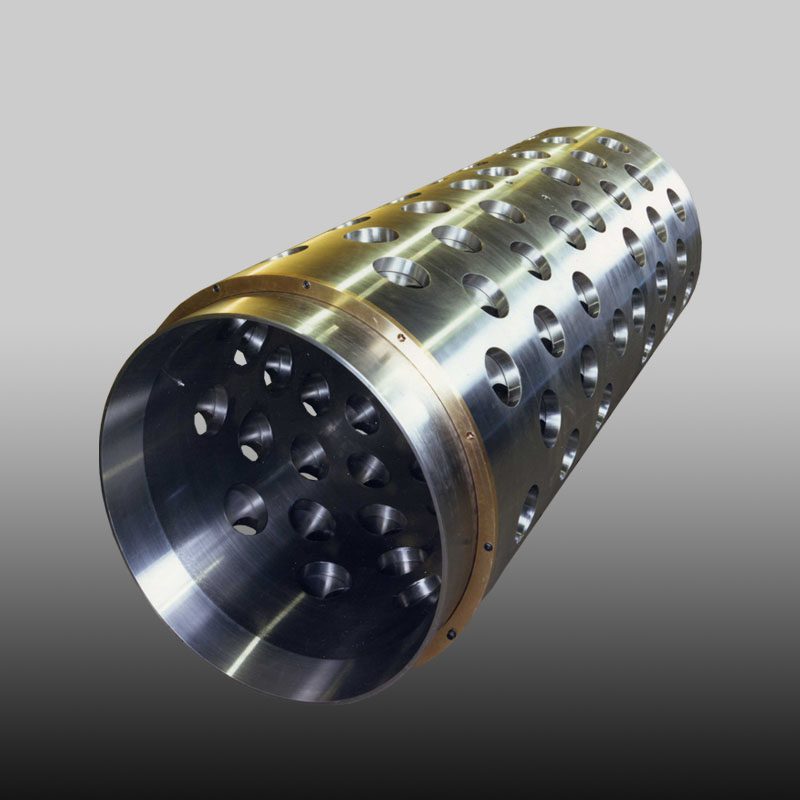

Over the years, the Sandusky product line has grown to include Polycast Shells and shell products for use as suction rolls, felt rolls, and press rolls. In addition, our customers have benefited from our many years in the development of stainless-steel alloys. Sandusky brings certified stainless-steel ingot and toll melting services to the stainless-steel casting market.

Customers designing, manufacturing, or operating papermaking machinery rely on Sandusky International for the world's leading roll shell products. Utilizing a deep understanding of the demanding environments in which our pulp and paper customers operate, Sandusky provides products and solutions to extend roll life and reduce operating and maintenance costs for paper mills everywhere.

Typical Papermaking Products

-

Dryer felt rolls

-

Lump breaker rolls

-

Paper rolls

-

Polycast shells

-

Press felt rolls

-

Reel spools

-

Suction roll shells

-

Winder roll shells

-

Wire turning rolls

Industrial Products

In addition to papermaking products, Sandusky is a leader in large-diameter cylinders in long, unwelded lengths for applications including Mining, Defense, Steel mills, and Energy. Using the centrifugal casting process, we offer unparalleled flexibility in dimensions, composition, and properties for your critical components that simply cannot fail.

Processes and Capabilities

Experts in large centrifugal casting and machining, Sandusky metal rolls come in sizes up to 60" (1,524 mm) in outer diameter (O.D.) and 432" (11 m) in length, weighing up to 125,000 pounds (56,700 kg). Serving Pulp & Paper and other high-specification markets, we leverage the resources of the entire MetalTek family to offer a wide range of metals expertise. Providing additional services such as heat treatment and reverse engineering, we invite you to contact us to learn more about our advanced design and manufacturing of large centrifugal castings.

Casting Sizes

-

O.D. of 12" to 60" (305 mm to 1,524 mm), length up to 432" (11 m)

-

Non-ferrous and carbon steel up to 80,000 lbs. (36,287 kg) pour weight

-

Stainless steel up to 125,000 lbs. (56,700 kg) pour weight / cast weight

Other Capabilities

-

Argon oxygen decarburization (AOD) processing

-

Automated stress relief

-

Machining up to 600" (15 m) in length and 200,000 lbs. (90,718 kg)

-

Solidification modeling

-

Twist drilling and smooth drilled holes (SDH)

-

Gun drilling available through outside machining partners

-

Recycling and environmental programs

Materials

Sandusky International specializes in just about any ferrous high-performance alloy. In addition to industry standard alloys, MetalTek regularly works with customers to modify grades to deliver the performance needed for their particular application and environment.

Suction rolls made from our patented Alloy 86® duplex stainless steel, DSA06, and CA-15 are recognized as the industry standard for long life and reliability. Paper mills looking to extend lifecycles and reduce the cost of unplanned failures rely on Sandusky for their replacement roll needs.

For more information on MetalTek alloy capabilities, visit our alloy guide.

Ingot

Sandusky International also provides certified ingot (including AOD-refined Ingot) in a variety of alloy families:

-

All 300 Series Stainless Ingot

-

All 400 Series Stainless Ingot

-

All Duplex Grade Ingot

-

All Tool Steel Ingot

-

All Monel Ingot

-

All Nickel Based Alloy Ingot

-

All Low Alloy Steel Ingot

Accreditations and Certifications

Like all MetalTek facilities, Sandusky International is equipped with an on-site chemical and mechanical laboratory. Certifications include:

-

ISO 9001:2015 (QMS)

-

ASTM, ASME, and military specifications

contact us

To contact Sandusky International Division please call 1-419-626-5340.

SANDUSKY INTERNATIONAL

510 West Water Street

Sandusky, OH 44870

PH: 1.419.626.5340

FX: 1.419.626.3339

Find your sales engineer for Sandusky International.

Solutions

Accumulator Tubes

MetalTek leads the Accumulator market offering the largest selection of size, centrifugal dies, and manufacturing capabilities.

Briquetting Rolls

MetalTek is experienced in centrifugal casting CDA 815 chrome copper which is commonly used in food applications.

Shaft Sleeves

Propulsion shafting for ocean-going Military and Commercial vessels is a critical and expensive part of the propulsion system.