Power Transfer

High-Strength And High-Wear Components For The Toughest Power Transfer Applications

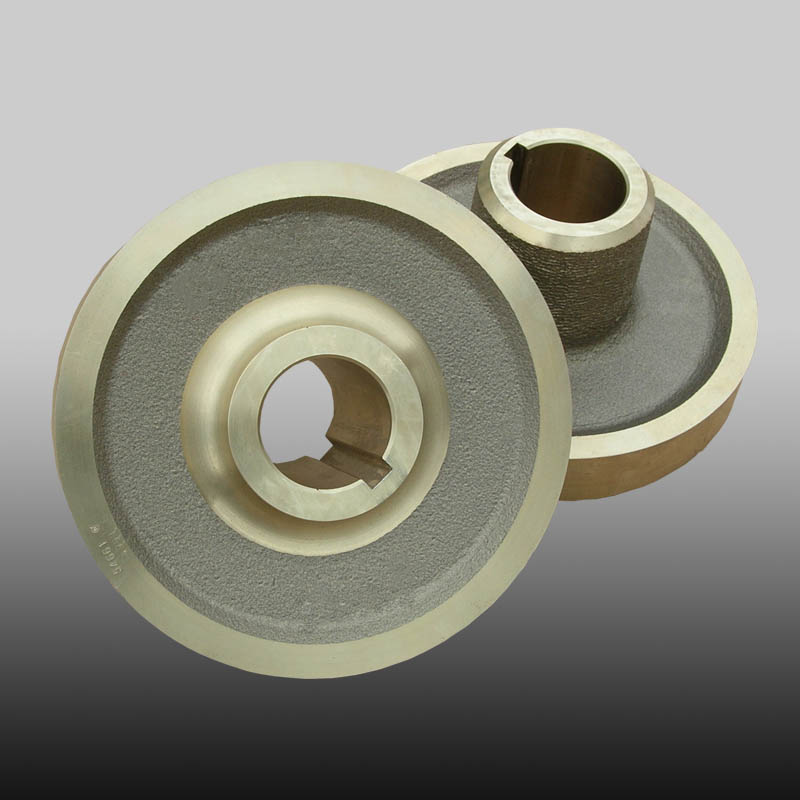

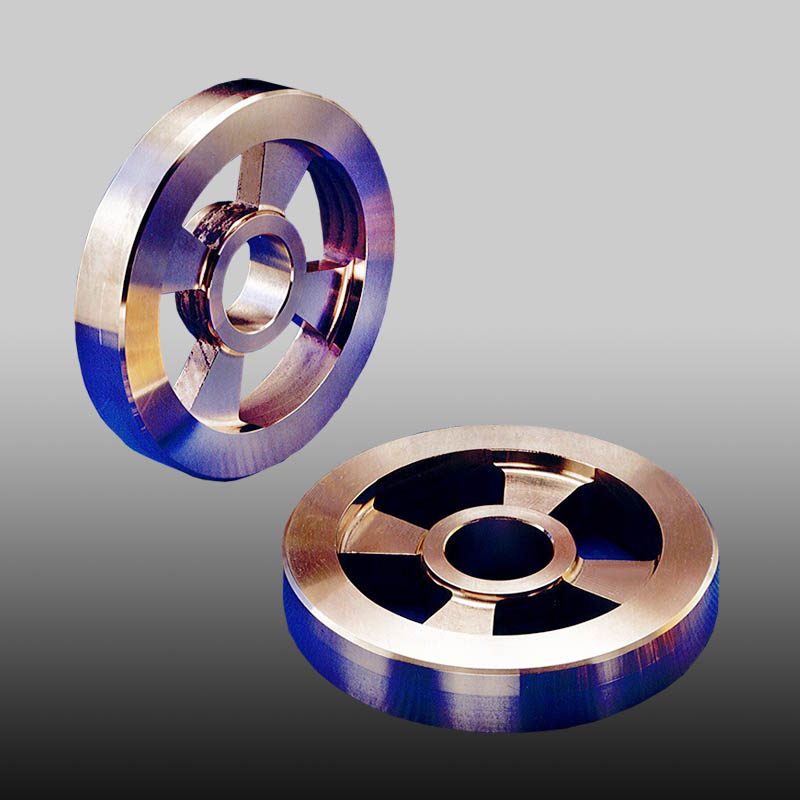

MetalTek helps push the limits of performance for tough and high-wear power transfer applications. Centrifugal casting is the metal casting process of choice for round wear components such as crane drums, bearings, and bushings. Proprietary Bearium bronze is an established leading option for applications where friction is extreme or ongoing lubrication is difficult. Finish machined components, such as gear boxes, hoists, and winches, are provided from multiple locations for quick turnaround jobs for wear-resistant applications.

MetalTek metallurgists recommended changes to a customer’s specifications for landing gear components, moving to components made of AMS 4880. This nickel aluminum bronze alloy not only matched the high-wear demands of the application but also provided significant cost savings over forgings. MetalTek’s extensive stock of rectangular, hollow, and solid AMS 4880 enables quick delivery of bushings, sleeves, and other shaped parts, ensuring you get the best value for your investment.

Typical power transfer products

-

Bearings

-

Bushings

-

Crane drums

-

Gear blanks

-

Wear rings

Typical power transfer applications

-

Construction equipment

-

Cranes

-

Drives

-

Gear boxes and speed changers

-

Hoists

-

Landing gear

-

Machine tools

-

Winches

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.

Solutions

With a broad range of alloys and metal casting processes, MetalTek has the technical expertise to help power transfer customers increase performance and manage costs while meeting the growing demands of their industries. View our range of solutions below and for custom solutions please contact the experts at MetalTek.