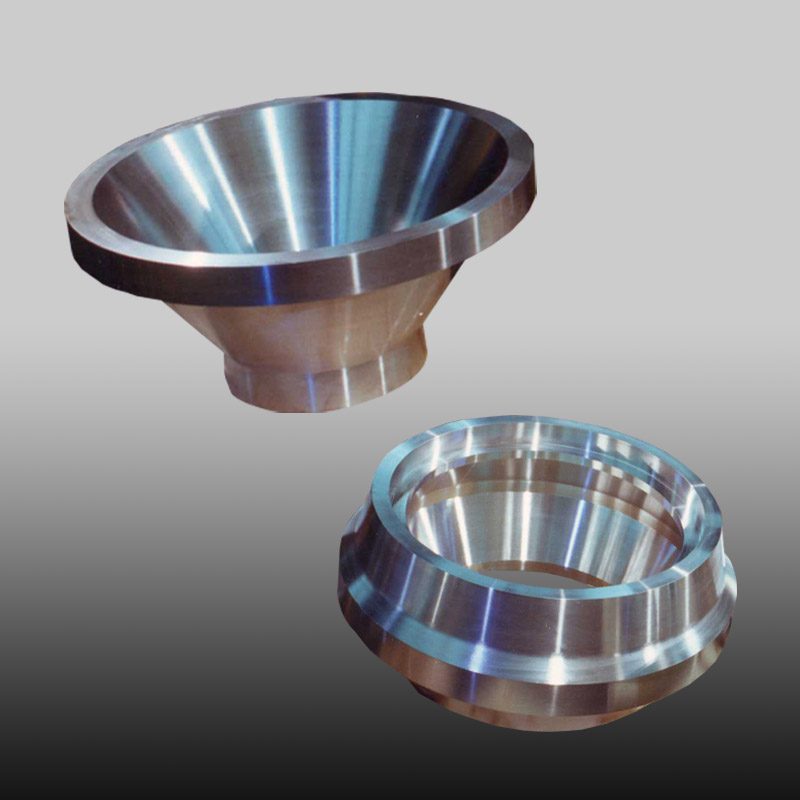

When a company’s regular supplier failed to meet delivery requirements, they came to MetalTek for assistance. Working with the client as a Metals Partner, MetalTek met their needs manufacturing centrifuge bowls out of Ferralium® 255 to obtain a balance of corrosion resistance, strength, and machinability. MetalTek routinely makes and pours over 400 alloys and our Metallurgists can assist you in selecting the proper one for your application. High speed rotating equipment like centrifuges rely on bowls that are balanced and consistent in shape and density. Those are qualities that describe centrifugal castings and make them a natural selection for this application. Centrifugal castings keep their inherent round shape, and their homogeneous grain structure produces consistent finish‐machined product. Perfect for centrifuge bowls. This is just one of countless examples where MetalTek acted as a solution provider for a customer.

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.

Markets

MetalTek Sales Engineers are industry specialists and understand the demands and subtleties of their markets. In regular customer satisfaction research, customers say that MetalTek people understand not only their own business, but also the issues that are important to their customers and to their customers’ industries. We only succeed when you are successful.

See Our Solutions Gallery

MetalTek is trusted by companies from around the world to create components in high-heat, high-wear, and high-corrosion environments from the depths of the ocean all the way to the surface of Mars. Click on the link below to see a broad range of solutions MetalTek has completed.