Steel Mills

High-wear steel mill applications demand solutions from MetalTek

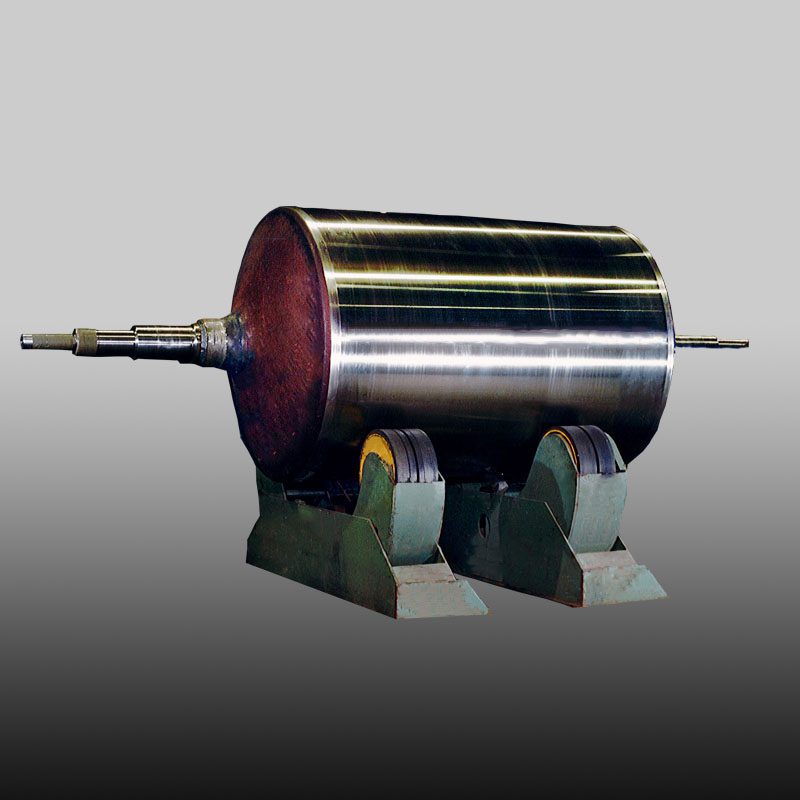

Heat-resistant alloys, corrosion-resistant alloys, the capability to produce large-size rolls, and a variety of shaft and trunnion designs contribute to MetalTek’s leading position as a provider of castings for steelworking markets. Our ability to manufacture and fabricate all components in house allows us to provide complete assemblies, saving customers time and money.

MetalTek’s proprietary high-wear alloy Bearium B-10 operates with very low levels of lubrication, resulting in significantly less wear than other alloys. Steel mill customers take advantage of the consistency and homogeneous qualities of MetalTek’s centrifugal castings for steel mill rolls, which outperform other manufacturing methods.

Typical Steel Mill Products

-

Blast furnace blowpipes

-

Bushings

-

Combustion tubes

-

Furnace rolls

-

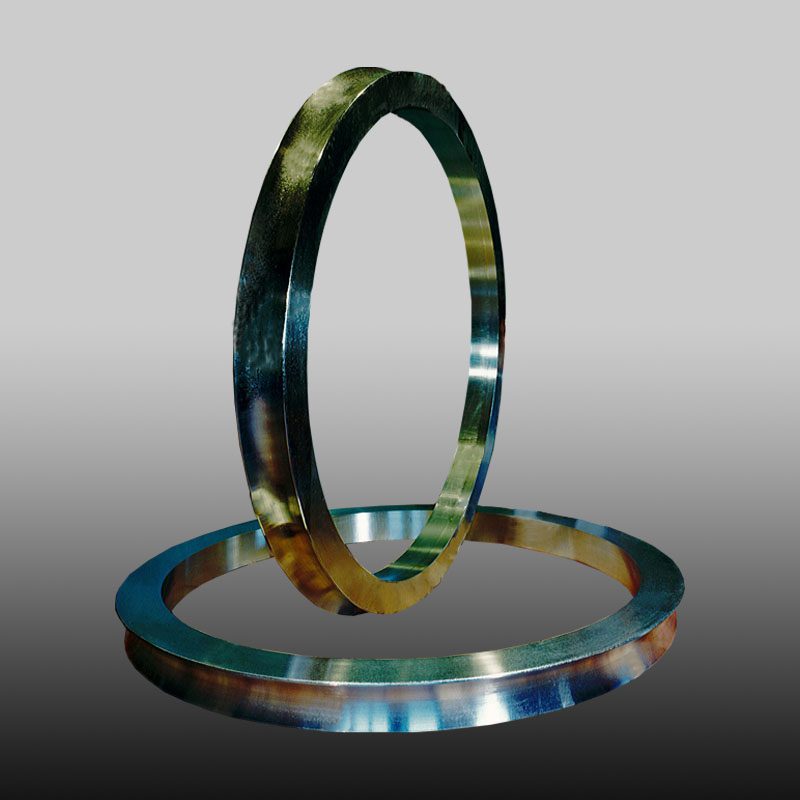

Electro-galvanizing bands

-

Gears, worm gears

-

Grate bars

-

Radiant tubes

-

Retorts

-

Roll trunnions

-

Sink rolls

-

Tuyeres

-

Wet rolls/dry rolls

Typical Steel Mill Applications

-

Electro-galvanizing lines

-

Heat treat furnaces

-

Steel mill furnaces

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.