Sandusky International

Sandusky International: World’s Largest Centrifugal Castings

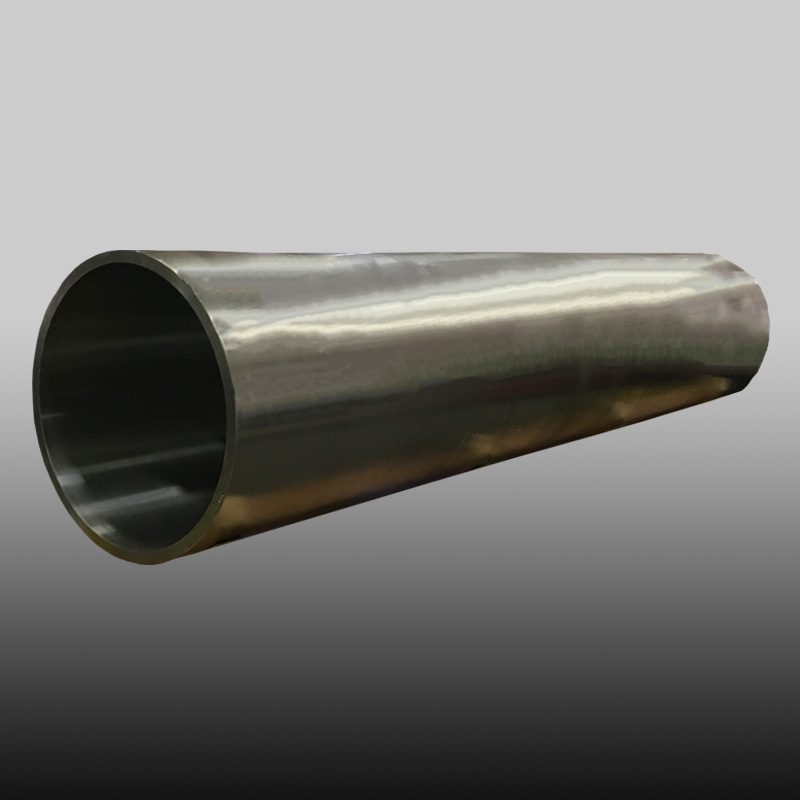

Sandusky International produces large centrifugal castings for high-heat, high-wear, and high-corrosion applications. Our centrifugal castings are among the largest in the world, up to 36 feet (11 meters) in length and five feet (1.5 meters) outer diameter (OD). Since our founding in 1904, Sandusky International has continually pushed the limits of centrifugal casting and now offers unmatched expertise in dimensions, properties, and quality.

This integrated alloy and manufacturing process expertise allows us to serve demanding industries such as defense, energy, paper, power transfer, and process equipment. What sets Sandusky International apart is not just the scale of our centrifugal castings but also the comprehensive range of in-house capabilities that ensure favorable lead times and consistent quality for our customers. Contact us to learn more.

Centrifugal Casting Sizes

-

Length up to 36 ft. (11 m)

-

OD up to 5 ft. (1.5 m)

-

Finished wall thickness up to more than 6 in. (15 cm)

-

Pour weight up to 125,000 lbs. (56,700 kg)

Other In-House Capabilities

-

Expertise in many ferrous and non-ferrous alloy grades

-

Argon oxygen decarburization (AOD) capacity of 40,000 lbs. (18,143 kg)

-

Chemically-certified ingot and toll melting services

-

Heat treat up to 85 in. (2.2 m) diameter and 450 in. (11.4 m) length

-

Machining up to 50 ft. (15 m) length and 200,000 lbs. (90,718 kg)

-

Laboratory services and non-destructive testing (NDT)

Sandusky International: Growing With Purpose

Where is Sandusky International headed? We are growing with purpose: with the right people, the right processes, and in the right industries.

Sandusky International: Target Markets

Sandusky International is a leading supplier of critical metal components for a range of high-heat, high-wear, and high-corrosion applications in the world's most demanding industries. Don't see your market? Please contact us to determine if Sandusky International's capabilities are a good fit for your application.

View All Markets

Product Examples

Sandusky International produces critical metal components such as:

-

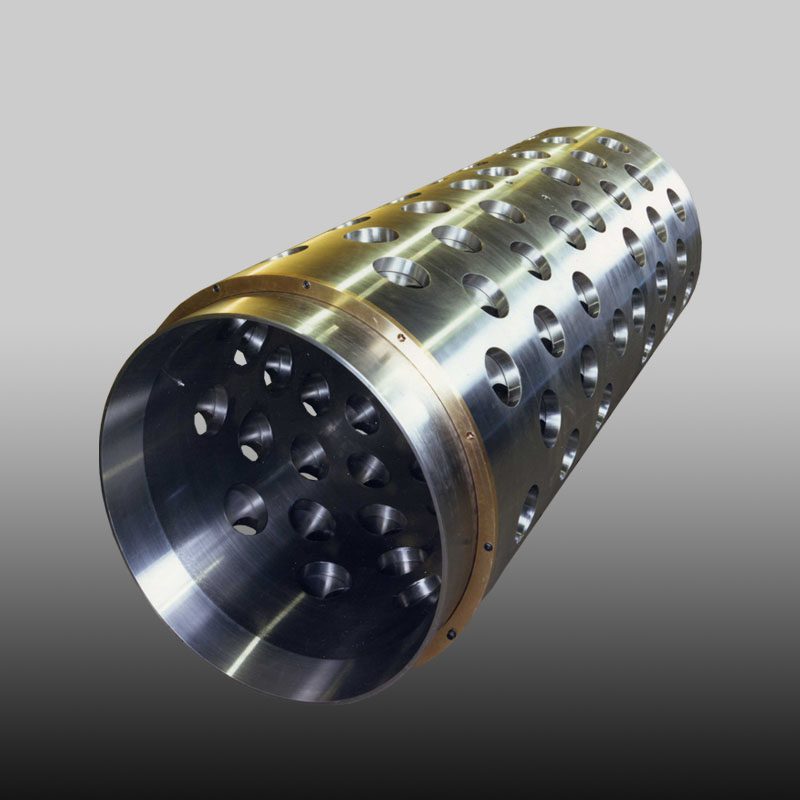

Accumulator tubes

-

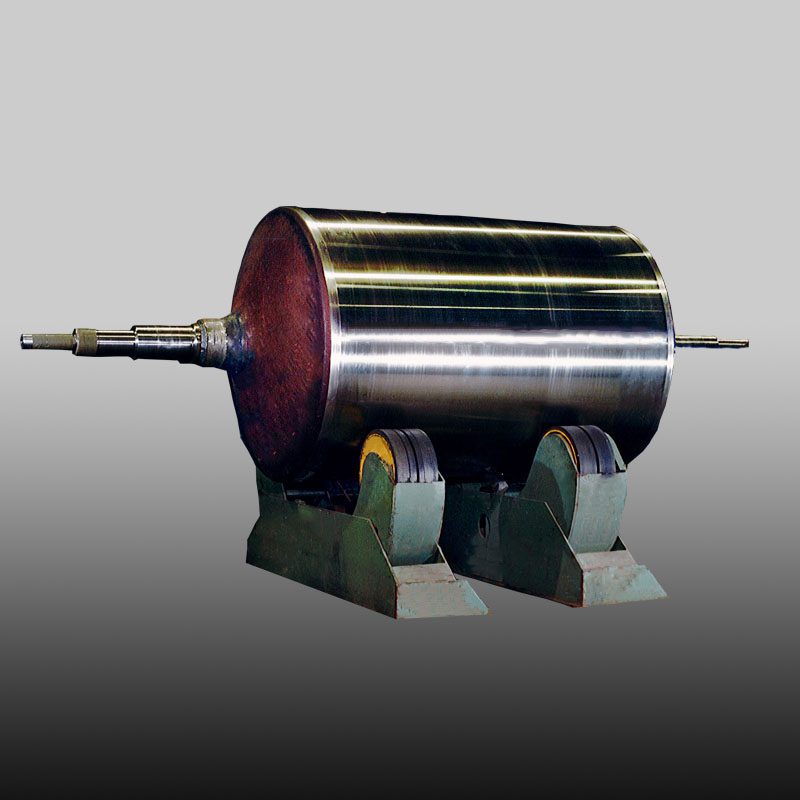

Annealing rolls

-

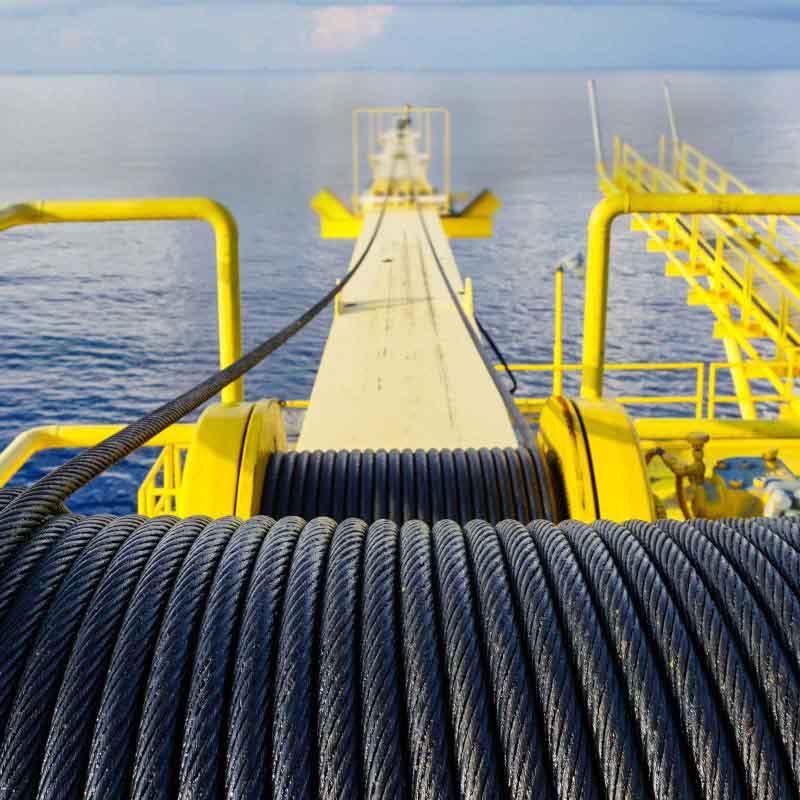

Crane drums

-

Hydraulic cylinders / hydraulic rams

-

Meter provers

-

Shaft sleeves

-

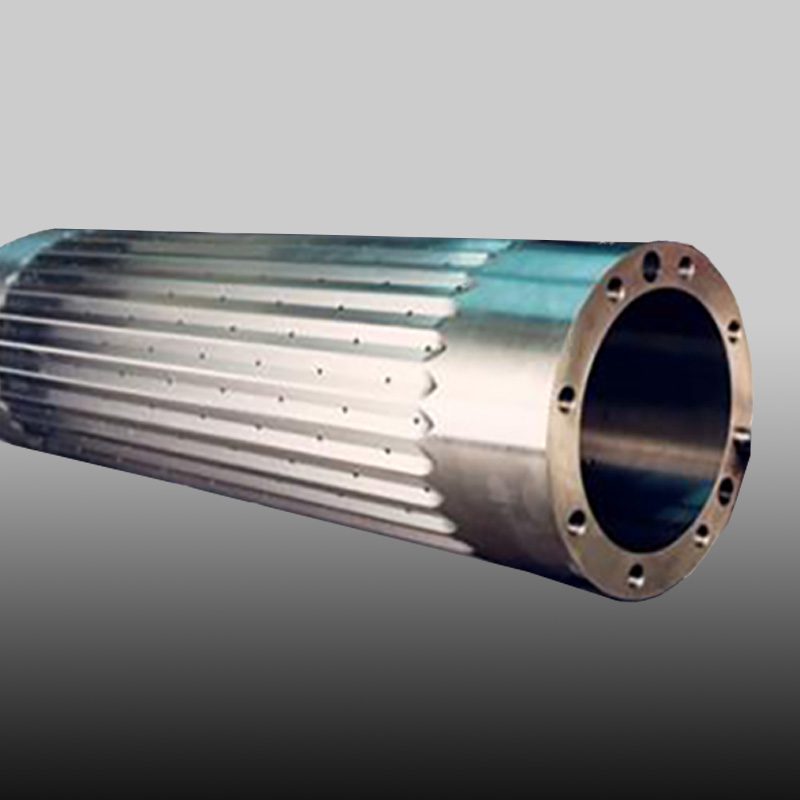

Suction roll shells

Certifications

Sandusky International's certifications include:

-

ISO 9001:2015 (QMS)

-

ASTM, ASME, and military specifications

contact us

Sandusky International

510 West Water Street

Sandusky, OH 44870

Phone: 1.419.626.5340

Find your market-based Key Account Manager for Sandusky International.

Solutions

Accumulator Tubes

MetalTek leads the Accumulator market offering the largest selection of size, centrifugal dies, and manufacturing capabilities.

Briquetting Rolls

MetalTek is experienced in centrifugal casting CDA 815 chrome copper which is commonly used in food applications.

Shaft Sleeves

Propulsion shafting for ocean-going Military and Commercial vessels is a critical and expensive part of the propulsion system.