Carondelet

Carondelet: Sand Castings For The World's Most Demanding Applications

Carondelet produces ferrous sand castings up to 18,000 pounds (8,165 kilograms) ship weight for demanding applications such as defense, mining, petrochemical, and process equipment. We are trusted by hundreds of customers who rely on our expertise in high-heat, high-wear, and high-corrosion environments. Notably, Carondelet is one of few manufacturers qualified to produce HY-80 sand castings to Naval Sea Systems Command (NAVSEA) Technical Publication T9074.

With more than 130 years of experience since our founding in 1890, Carondelet combines integrated alloy and manufacturing process expertise with a state-of-the-art, highly automated facility. This makes Carondelet a preferred supplier for small to medium-sized production runs of high-specification, sand-casted metal components. Our commitment to Making a Lasting Difference is exemplified by projects such as the Pentagon Memorial. Contact us to learn how Carondelet can use our technical expertise to meet the unique demands of your application.

Sand Casting Sizes

-

Size up to 144 in. (3.7 m) cube

-

Pour weight up to 36,000 lbs. (16,360 kg)

-

Ship weight up to 18,000 lbs. (8,165 kg)

Other In-House Capabilities

-

Expertise in over 300 alloy grades

-

Pattern shop including traditional matrials as well as 3D printing

-

Molding includes IMF, patternless, automated isocure, no-bake, and pit

-

Argon oxygen decarburization (AOD) capacity of 10,000 lbs. (4,536 kg)

-

Heat treat up to 5 ft. x 10 ft. x 17 ft. (1.5 m x 3.0 m x 5.2 m)

-

Laboratory services and non-destructive testing (NDT)

Carondelet: HY-80 Steel Certification

Carondelet is one of few manufacturers qualified to produce HY-80 sand castings to NAVSEA Technical Publication T9074. HY-80's strength, toughness, and corrosion resistance make it ideally suited for naval defense applications, including submarines and surface ships.

Carondelet: Target Markets

Carondelet is a leading supplier of critical metal components for a range of high-heat, high-wear, and high-corrosion applications in the world's most demanding industries. Don't see your market? Please contact us to determine if Carondelet's capabilities are a good fit for your application.

View All Markets

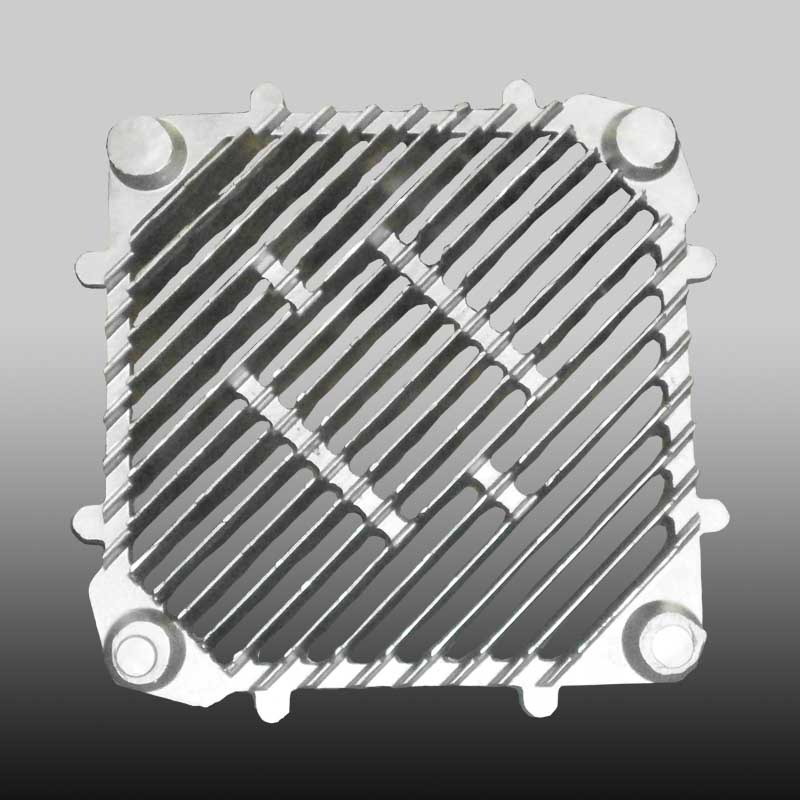

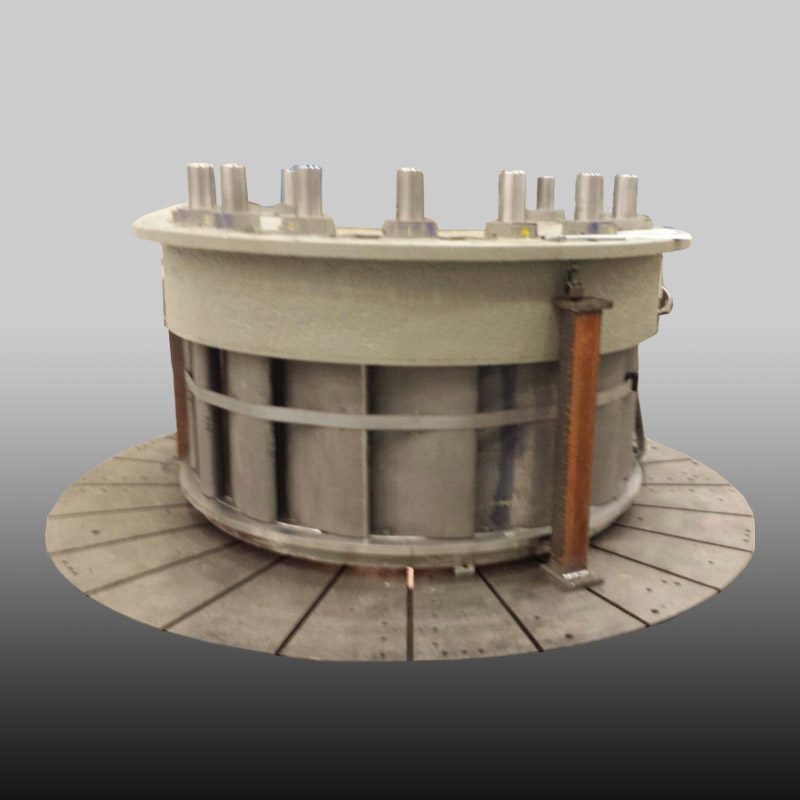

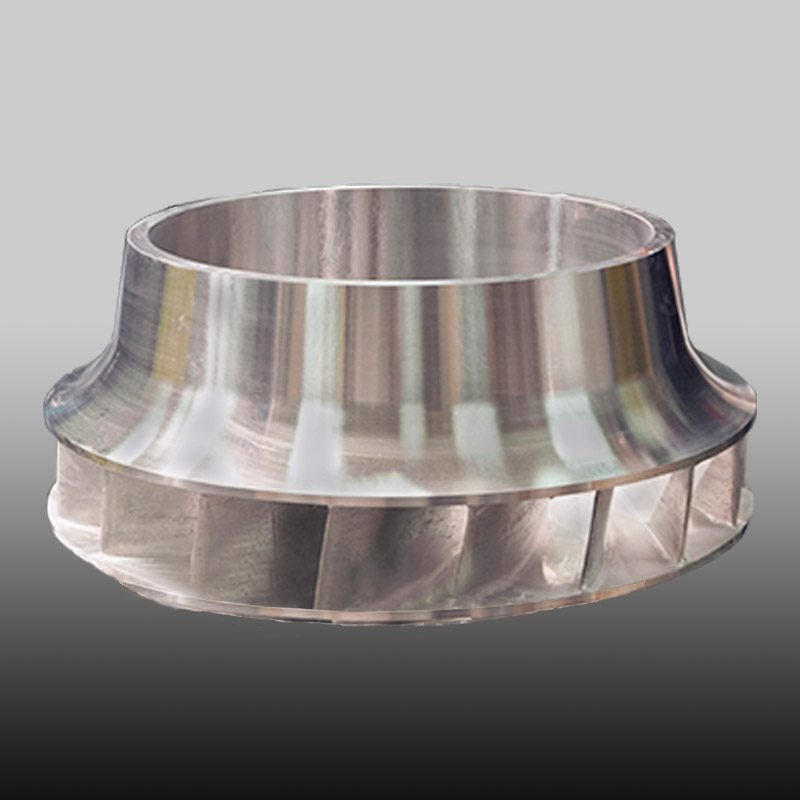

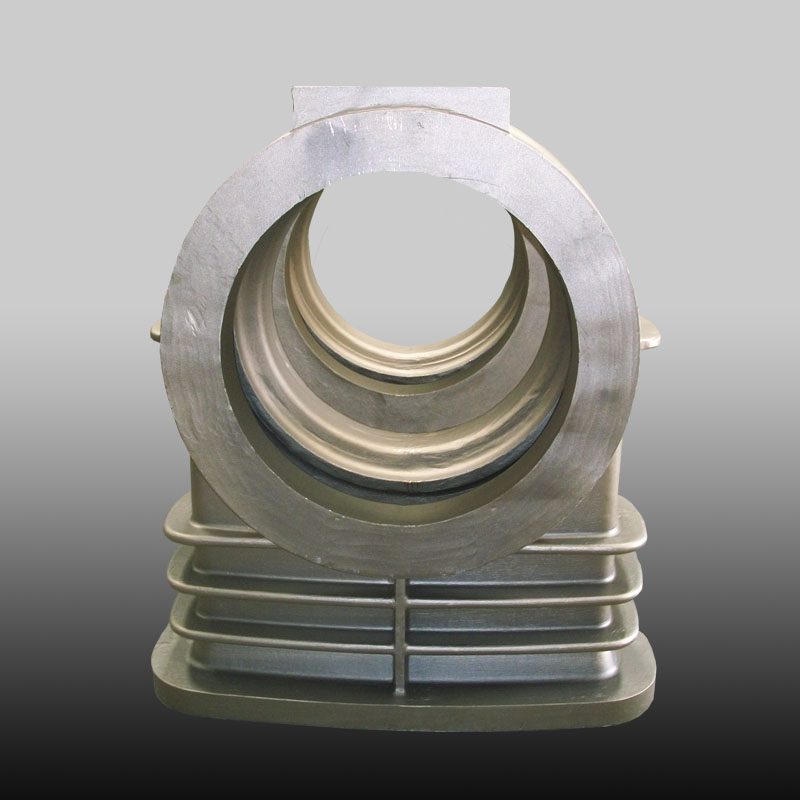

Product Examples

Carondelet produces critical metal components such as:

-

Francis turbine runners

-

Mining traveling grates

-

Petrochemical fittings

-

Petrochemical tube sheets

-

Structural supports for defense applications

-

Submarine hatch covers

-

Valves and valve components

Certifications

Carondelet's certifications include:

-

HY-80 to NAVSEA Technical Publication T9074

-

Inspectors to ASNT-TC-1A Level II

-

ISO 9001:2015 (QMS)

-

NORSOK M650 Rev 4 (Duplex Grade 4A, Super Duplex Grade 5A, Super Austenitic CK3MCuN)

-

PED (Pressure Equipment Directive) Material Manufacture

contact us

Carondelet

8600 Commercial Boulevard

Pevely, MO 63070

Phone: 1.636.479.4499

Find your market-based Key Account Manager for Carondelet.