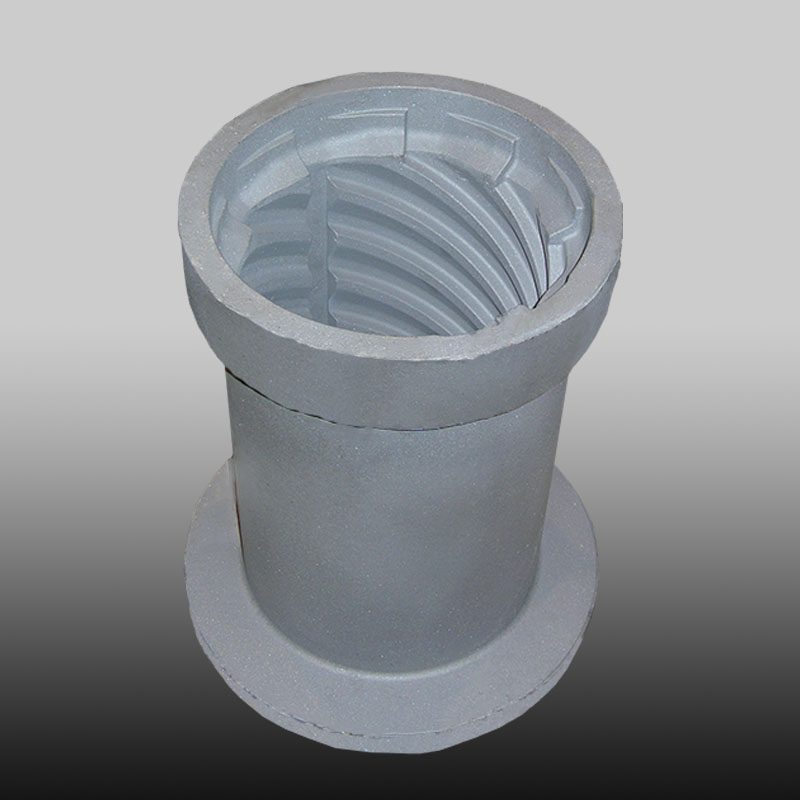

Fabrications require extensive metal forming, welding, and polishing manpower to produce a part that meets stringent USDA surface finish and specified design requirements. Even when those requirements can be achieved in a fabrication, the end product can often vary lot-to-lot, making interchangeability and consistent performance an issue. MetalTek’s Wisconsin Investcast Division successfully converted a complicated fabrication into a single large investment casting. This 280 lb./127kg stainless steel casting features nine spiraling flutes that contour along its entire length and contains as-cast surfaces that satisfy USDA requirements. As a result, the customer has enjoyed the benefits of significant labor savings, manufacturing capacity, consistency of production parts, and increased process throughput.

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.

Markets

MetalTek Sales Engineers are industry specialists and understand the demands and subtleties of their markets. In regular customer satisfaction research, customers say that MetalTek people understand not only their own business, but also the issues that are important to their customers and to their customers’ industries. We only succeed when you are successful.

See Our Solutions Gallery

MetalTek is trusted by companies from around the world to create components in high-heat, high-wear, and high-corrosion environments from the depths of the ocean all the way to the surface of Mars. Click on the link below to see a broad range of solutions MetalTek has completed.