Blog Archives

Grade MTEK A2 (T90102 / CA2) Tool Steel Description Air-hardening medium-alloy cold work steel Properties – Why select this material Excellent non-deforming properties Wear and abrasion resistance Good machinability in annealed condition Applications – Frequent uses Cold draw dies Rolling dies Grade MTEK A6 Tool Steel Description Air-hardening medium-alloy cold work steel Properties – Why…

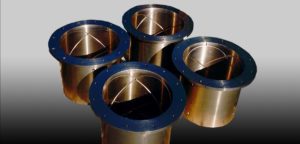

Read MoreMetallurgically, Bronze is a copper-based metal alloyed with tin, lead, aluminum or other elements to change the material’s physical or mechanical properties. The historic “Bronze Age” stretched from around 3000 B.C. to about 1000 B.C. Early craftsmen found the material easier to deal with than stone for many uses, and more durable than other materials…

Read MoreIron Chrome (Fe-Cr) Alloys. This group includes the grades HA, HC and HD. Description This family of stainless steel is often used in higher temperature but lower stress applications. Properties – Why select this material Effective in load-bearing applications at temperatures up to 1200°F-1300°F/650°C-700°C). HA is used for components in low-stress applications. Resistant to high…

Read MoreGrade Nitronic® 50 (J93790 / CG6MMN / Licensed by Armco, Inc.) Description Low carbon austenitic stainless steel Nitronic 50 Material Properties – Why select this material The most corrosion resistant alloy in the Nitronic family. Mechanical properties and corrosion resistance are superior to published values for CF8/304 and CF8M/316. Excellent performance in acidic, chloride and…

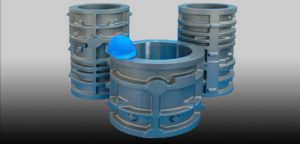

Read MoreCentrifugally cast components are typically thought of as straight walled cylindrical geometries such as tubes, pipe, or rings. They are often cast horizontally in permanent steel dies that have a removable end cap. Because the part must be extracted from the uncollapsible die, shaping is limited to geometries that have a straight or slightly drafted O.D. …

Read MoreIf you Google “Casting Terminology”, you get over 50 million results. Some of the results will show you a never-ending list of terms so here is a reduced list of select terms that you should be familiar with as a current or potential user of metal castings. To see a complete list of terms on…

Read More