Blog Sandusky International: Largest Centrifugal Castings for Demanding Industries Worldwide

By: David Stuck

MetalTek’s Sandusky International Division is a leading supplier of large metal components for high-heat, high-wear, and high-corrosion applications in a range of demanding industries. Founded in 1904 to primarily serve the paper industry, Sandusky International evolved over subsequent decades and now serves markets as diverse as:

- Defense

- Energy (including oil & gas)

- Power Transfer

- Process Equipment

- Renewable Energy

- Steel Mills

In 2023 Sandusky International secured a substantial order from a defense customer, underscoring how we have successfully diversified our customer base. This milestone is emblematic of our dedication to pushing the limits and finding solutions to complex customer challenges.

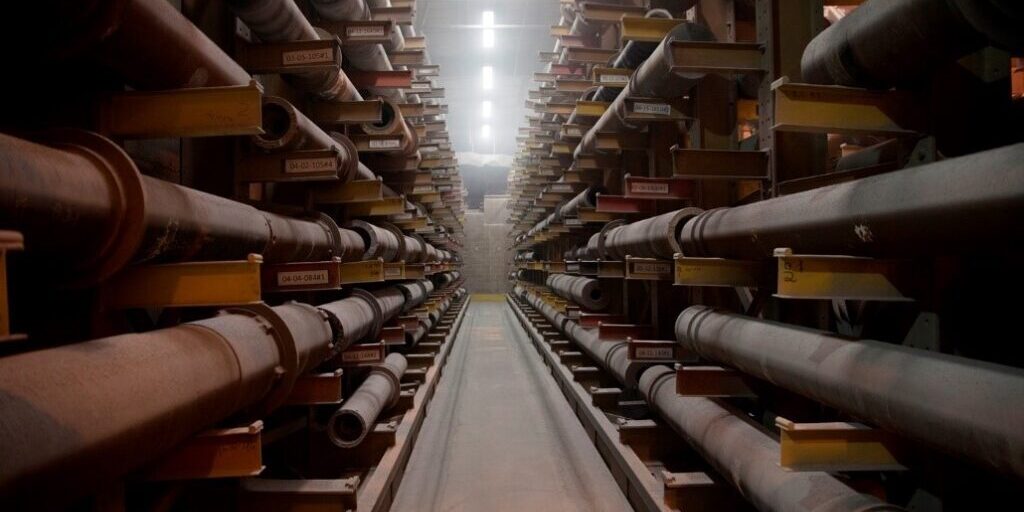

Expertise in Large Centrifugal Castings

Sandusky International secured this defense order due primarily to our expertise in centrifugal casting, which involves pouring molten metal into a spinning die to produce symmetrical metal parts in the shape of shells, tubes, or cylinders. The defense customer considered other metal casting methods for its part, but experienced issues related to poor solidification and porosity with these other methods.

How did centrifugal casting address these challenges? High centrifugal force applied to molten metal during the centrifugal casting process results in consistent solidification and a defect-free structure. This makes centrifugal casting an ideal choice for the defense customer’s specific application.

Sandusky International has 120 years of experience in centrifugal casting. What sets us apart from other metal component manufacturers is our ability to produce the largest centrifugal castings in the world from both ferrous and non-ferrous alloys. Our scale means that we can often produce multiple customer parts from just a single centrifugal casting.

Our centrifugal casting capabilities include:

- Pour weight: up to 125,000 lbs. (56,700 kg)

- Finished outer diameter (OD): up to 5 ft. (1.5 m)

- Length: up to 36 ft. (11 m)

- Finished wall thickness: up to more than 6 in. (15 cm)

Our casting equipment at Sandusky International includes two (2) 10-ton electric arc furnaces, four (4) five-ton induction furnaces, and a 20-ton capacity argon oxygen decarburization (AOD) vessel. AOD is a process for refining ferrous metals such as stainless steel to reduce carbon content in the metal and improve mechanical properties such as strength, corrosion resistance, and heat resistance.

These centrifugal casting capabilities allow us to offer unmatched expertise in dimensions, properties, and quality. However, Sandusky International’s manufacturing process expertise extends beyond just centrifugal casting.

Comprehensive In-House Capabilities

We have comprehensive machining capabilities located onsite at our 250,000 sq. ft. (23,000 sq. m) facility in Sandusky, OH. These include the largest horizontal boring mill in the world, capable of removing up to 2.5” on a side in a single pass. Our complete machining capabilities include:

- High-volume twist drilling

- Turning lathes: OD to 120” (3 m), max length 597” (15 m)

- Boring lathes: inner diameter (ID) to 58” (1.5 m), max length 600” (15 m)

- Vertical turret lathes: OD to 63” (1.6 m), max length 54” (1.4 m)

- Milling: OD to 66” (1.7 m), head reach to 26” (0.7 m), ID to 63” (1.6 m), length to 500” (13 m)

Other in-house capabilities include heat treat for diameters up to 85” (2.2 m) and lengths up to 450” (11 m) as well as non-destructive testing (NDT), inspection, and lab services to meet the strictest customer quality requirements.

What does this all mean? Sandusky International is well positioned to meet the diverse demands of the world’s most demanding industries, including defense.

Integrated Alloy and Manufacturing Process Expertise

Increased work in industries such as defense holds immense promise, not only in terms of business growth but also in promoting Sandusky International’s integrated manufacturing process and alloy expertise. The 70-30 copper-nickel alloy provides strong resistance to corrosion and is particularly suitable for applications that operate in seawater. This makes 70-30 copper-nickel ideal for the defense customer’s application. Sandusky International has dozens of ferrous and non-ferrous alloys to help customers get the exact material properties they need for high-heat, high-wear, and high-corrosion applications.

For the team at Sandusky International, our big step into the defense industry holds personal significance. The knowledge that we directly contribute to the safety of our military and those who they protect instills a profound sense of pride and purpose. For many employees, it evokes memories of family members who served in the armed forces, deepening our connection to the mission at hand.

Why Sandusky International?

Sandusky International stands ready to serve a range of customers in the world’s most demanding industries. Our expertise in centrifugal casting spans well over a century and puts us at the forefront of diverse markets ranging from defense to energy and beyond. Sandusky International differentiates itself not only with our ability to produce the largest centrifugal castings in the world but also in our vertical integration that ensures favorable lead times and consistent quality for our customers.

Do Sandusky International’s capabilities sound like a good fit for your metal component or application? Contact us if you need help with a project or are simply interested in learning more about what we can do. Sandusky International remains ready to provide critical metal components for the world’s most demanding high-heat, high-wear, and high-corrosion applications. Join us as we remain committed to Making A Lasting Difference® by helping to power, protect, and connect our world.

About the Author

David Stuck is Sales Manager of MetalTek’s Sandusky International Division in Sandusky, OH.