Blog Specialized Metal Alloys For Pulp & Paper Applications

January 6, 2022

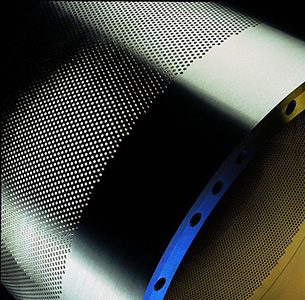

For decades, MetalTek’s Sandusky International division has centrifugally cast, precisely machined, and expertly drilled suction roll shells. If you partner with MetalTek, you get suction roll shell materials developed through technical expertise of what works and what doesn’t.

We offer multiple suction roll shell materials, from Alloy CA15 for mild environments to the unmatched performance of the patented Alloy 86 for the harshest, most highly loaded environments.

The below are specialized alloys for pulp & paper applications. If you have any questions on these, or any, metal alloys for your next project, contact us today.

Alloy 86

- Best Service Performance of Any Roll Shell

- Superior Performance in Highly Loaded Press Applications

- Superior Corrosion-Fatigue Strength in Corrosive Thiosulfate Containing White Waters

- Lower Residual Stress than Any Other Duplex Stainless

- Superior Resistance to Fatigue Crack Growth to Maximize Life

Alloy DSA06

- Superior Corrosion-Fatigue Strength in Aggressive White Waters, Similar Chemistry to A-86

- Competitive Cast Duplex with Excellent Resistance to Fatigue Crack Growth and Lower Residual Stress than Fabricated Rolled & Welded Shells

- Suitable for Nipped Applications

- Manufacture Cycle Times Reduced, Shortening Lead Times

Alloy EPV

- Excellent Resistance to Fatigue Crack Growth

- Superior Corrosion-Fatigue Strength in Aggressive White Water

- Same Base Chemistry as Alloy 86 With A Modified Heat Treatment

- Lower Residual Stress than Fabricated Rolled & Welded Shells

- In Service Since 1998

Alloy CA15

- Economical Martensitic Stainless Steel

- Very Good Corrosion-Fatigue Strength in Mild Environments

- Low Residual Stress to Maximize Life

- In Continuous Service Since 1954

Have questions?

Download Our Alloy Guide

Download Our Where Used Guide

Blog Tags

Related Blogs

8 Metals Commonly Used For Casting

Metal casting involves pouring molten metal into a die or mold to form a desired shape. Numerous types...

Bearium Metal Alloys: An in-depth guide of proprietary leaded bronzes

What Is Bearium Metal? Bearium Metal is a group of high lead tin bronze alloys containing virgin copper,...

Sandusky International: Largest Centrifugal Castings for Demanding Industries Worldwide

MetalTek’s Sandusky International Division is a leading supplier of large metal components for high-heat, high-wear, and high-corrosion applications...