Process Equipment

Process Industries Like Chemicals, Pump, Valve, Metering, Oil And Gas, And Water Rely On High-Integrity Components From MetalTek

Thousands of customers in countless process industries rely on MetalTek to help them push the limits of what is possible and improve their products.

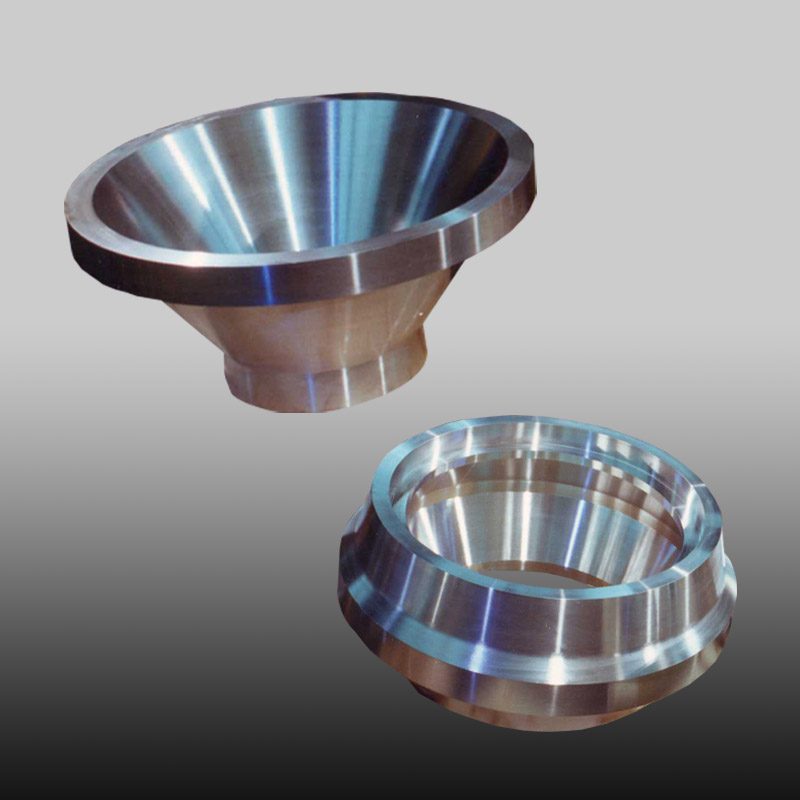

The process industry has a range of needs that demand high-integrity equipment components. Large centrifugal wear rings keep rotating parts reliably moving. The unique properties of centrifugal castings make them an obvious choice for centrifuge drums. Oil and gas markets demand products like MetalTek manganese bronze jack nuts that not only perform reliably in severe environments but operate well beyond industry standards. Valves for the Alaska Pipeline are produced using hybrid processes from MetalTek that all but eliminate machine scrap. Accumulator tubes from MetalTek are installed on the ocean floor and available in an unmatched range of sizes.

At MetalTek, we value our customers in the process industries and understand the importance of their unique needs. We work closely with every customer, fostering a collaborative environment that ensures their voices are heard and their needs are met. Whether it is drawing on the more than 400 alloys that MetalTek routinely pours, the shaping delivered by sand, investment, net shaped centrifugal castings, or complex machining and fabrications, customers in process industries rely on MetalTek for complex solutions to make their products safer and better. Please see our Energy page for other solutions related to process equipment.

Typical Process Industry Products

-

Bushings

-

Bearings

-

Centrifuge bowl shells

-

Flow meters

-

Pump housings

-

Pump impellers

-

Seal rings

-

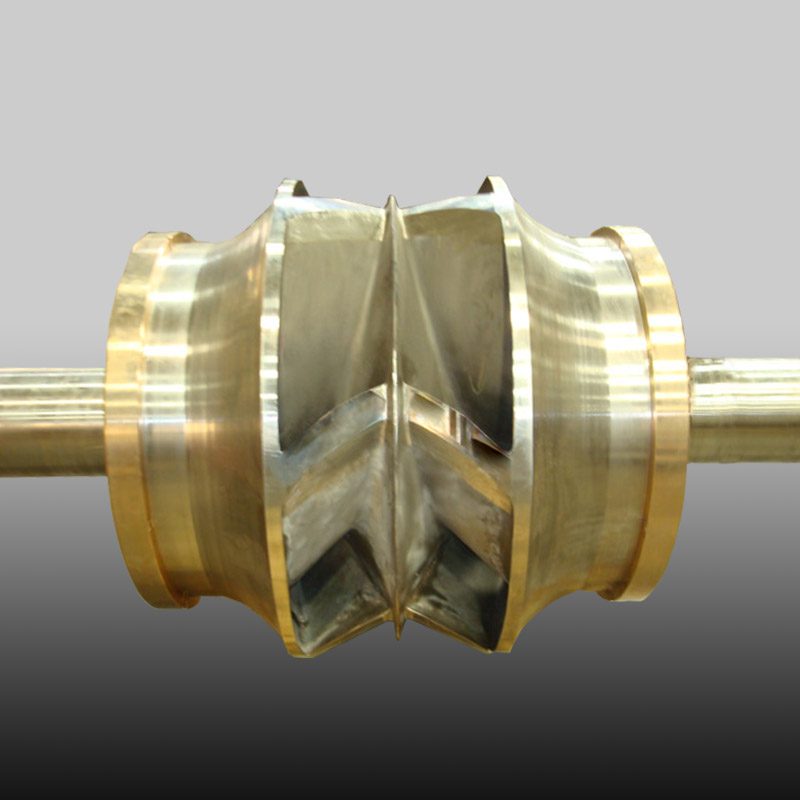

Swirlers

-

Valve bodies

-

Wear rings

Typical Process Industry Applications

-

Centrifuges / decanters

-

Desalination systems

-

Oil and gas production

-

LNG transport and metering

-

Pumps and valves

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.

Solutions

MetalTek takes pride in its ability to cater to a wide range of process industry applications. From bushings and bearings to flow meters and swirlers, our solutions are versatile and adaptable, ensuring that your specific needs can be met. Read more about specific solutions we have had tremendous success in.

Near-Net Shaped Centrifugal Valve Cages

MetalTek converted the static casting to a centrifugal, incorporating the sand core technology.

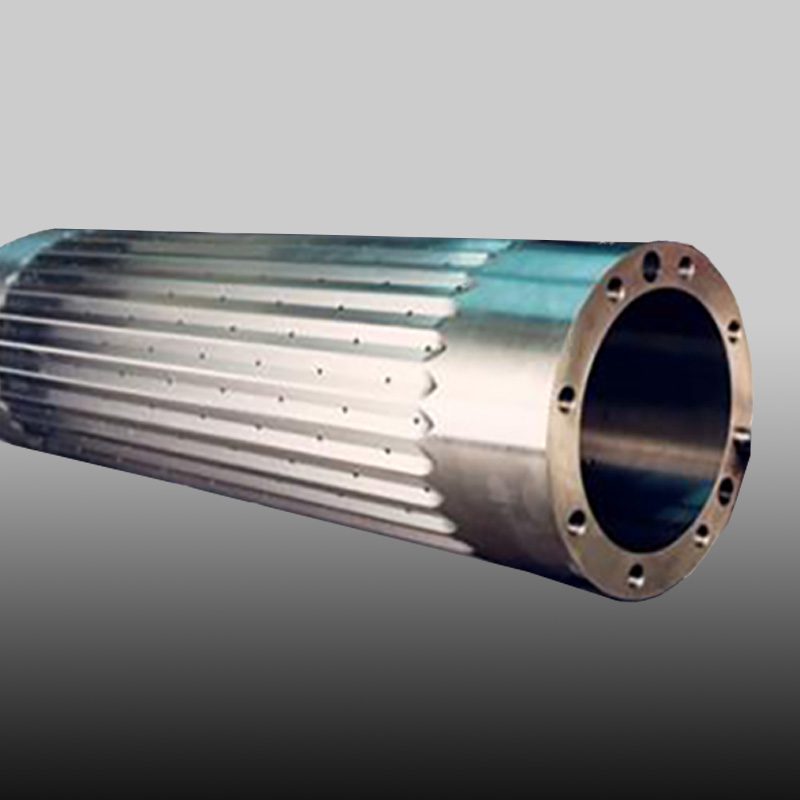

Vertical Centrifuge Components

Centrifugal castings keep their inherent round shape and their homogeneous grain structure.

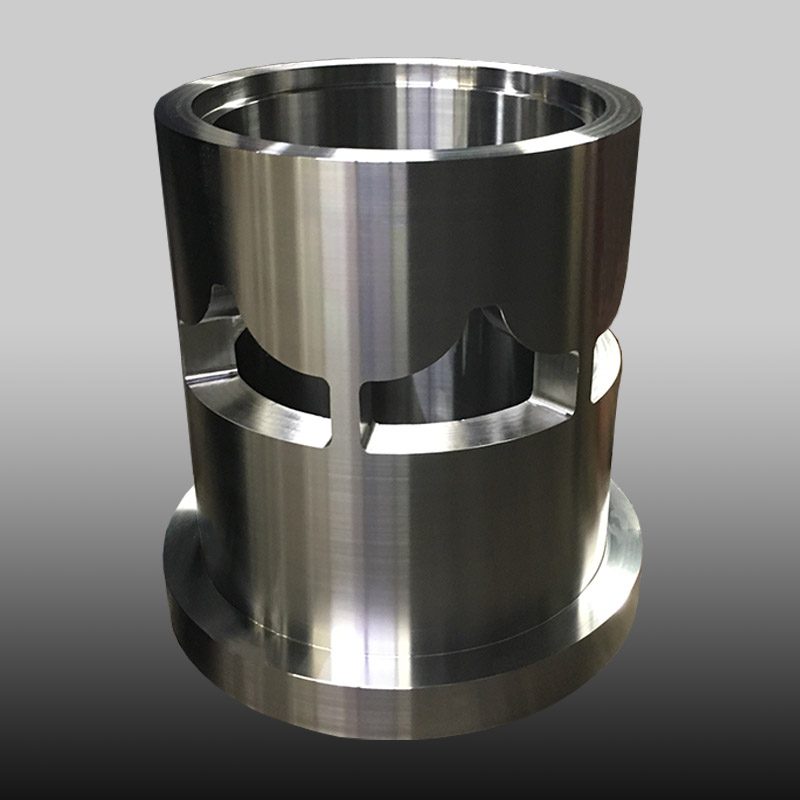

Gate Valve Body

Our proprietary HPLT casting process delivers products that perform with little or no weld upgrade.

Submersible Pump Motor Body

Submersible pump applications are often remote and in highly corrosive environments.

- « Previous

- 1

- 2