Blog Archives

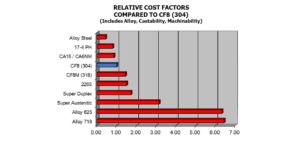

Every material selection decision includes tradeoffs. Performance can come at a price. But there is little sense in paying for capabilities that are not needed. The following suggests a framework for selecting one of a family of corrosion-resistant materials from another.

Read MorePress Release MetalTek International today announced that Chief Operating Officer E.J. Kubick has replaced Bob Smickley as Chief Executive Officer. This is part of the multi-year succession plan that began with Mr. Kubick’s appointment to the COO role in January 2017. Mr. Kubick and Mr. Smickley will both continue to serve on MetalTek’s Board of…

Read MoreEvery material selection decision includes tradeoffs. Performance can come at a price. But there is little sense in paying for capabilities that are not needed. The following suggests a framework for selecting one of a family of corrosion-resistant materials from another. Comparisons Cost Cost is rarely ignored, so it is helpful to compare certain corrosion-resistant…

Read MoreGrade Martensitic Stainless Steels. Description The addition of sufficient carbon to alloys of chromium and iron results in alloys that are true steels in that they can be hardened and tempered. Their structure upon rapid cooling from temperatures above 1600°F / 870°C is chiefly martensitic. Martensitic Steel Properties – Why select this material Magnetic…

Read MoreGrade MTEK 943 (C94300) Tin bronze Description Bearing alloy with the ability to operate at high speeds and light loads under adverse lubrication conditions. Properties – Why select this material Where deformation due to bad fit of components is an issue. Good conformability. It has fair strength and wear resistance, but excellent anti-frictional properties. It…

Read MoreGrade MTEK A2 (T90102 / CA2) Tool Steel Description Air-hardening medium-alloy cold work steel Properties – Why select this material Excellent non-deforming properties Wear and abrasion resistance Good machinability in annealed condition Applications – Frequent uses Cold draw dies Rolling dies Grade MTEK A6 Tool Steel Description Air-hardening medium-alloy cold work steel Properties – Why…

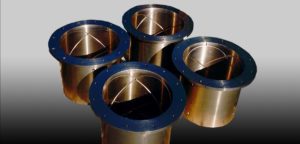

Read MoreMetallurgically, Bronze is a copper-based metal alloyed with tin, lead, aluminum or other elements to change the material’s physical or mechanical properties. The historic “Bronze Age” stretched from around 3000 B.C. to about 1000 B.C. Early craftsmen found the material easier to deal with than stone for many uses, and more durable than other materials…

Read MoreIron Chrome (Fe-Cr) Alloys. This group includes the grades HA, HC and HD. Description This family of stainless steel is often used in higher temperature but lower stress applications. Properties – Why select this material Effective in load-bearing applications at temperatures up to 1200°F-1300°F/650°C-700°C). HA is used for components in low-stress applications. Resistant to high…

Read MoreGrade Nitronic® 50 (J93790 / CG6MMN / Licensed by Armco, Inc.) Description Low carbon austenitic stainless steel Nitronic 50 Material Properties – Why select this material The most corrosion resistant alloy in the Nitronic family. Mechanical properties and corrosion resistance are superior to published values for CF8/304 and CF8M/316. Excellent performance in acidic, chloride and…

Read More