Blog Archives

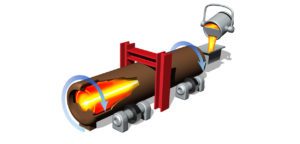

Advantages Centrifugal Casting Eliminates Mid-wall Defects The centrifugal process does not rely on discrete risers or feed points to ensure the absence of trapped porosity. Rather, the inner diameter remains fully liquid during the solidification process, resulting in a continuous supply of metal to feed areas of contraction. Unlike conventional gravity or static castings that…

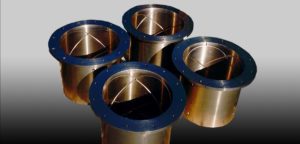

Read MoreFor over 60 years, Bearium® Metals have been chosen for performance under the toughest operating conditions. These are high lead tin bronze alloys containing virgin copper, tin, and specially processed lead. Bearium® metals can be used where other bearing materials may fail due to speed, load, temperature, or where lubrication is difficult, impossible, or simply…

Read MoreCobalt Metal Properties Cobalt based metals are alloyed with chrome, nickel, and tungsten. Due to the high cost of these alloys, they are used where severe conditions prevail and require high temperature strength and hardness, excellent wear, galling, corrosion, and/or erosion resistance. Due to the high chromium content (25% – 30% for the grades listed…

Read MoreNo engineering alloy is immune to corrosion; each has its own corrosion rate depending on the environment in which it is placed. This paper identifies some common types of corrosion, what the results of its presence may be, and how it may be minimized. What Are The Different Types of Corrosion? Uniform Corrosion This mode…

Read MoreWear is probably the most common cause of material replacement in the industry. Bushings and bearings are common examples of components which must provide metal-to-metal wear resistance. Wear is a universal constant in moving equipment in all applications. In some applications like food processing, the use of certain materials that provide superior wear resistance (copper-based…

Read MoreAbout 60% of the nickel in the world ends up as a component of stainless steel. It is selected because of its strength, toughness, and resistance to corrosion. Duplex stainless steels typically contain about 5% nickel, austenitics around 10% nickel, and the super austenitics over 20%. Heat resistant grades often contain over 35% nickel. Nickel-based…

Read MoreHow strong is copper? The answer is it depends on which copper-based alloy you choose. You can achieve superior corrosion resistance and/or durability in applications that require wear and galling resistance. Copper is a heavy metal that can provide the strength equivalent of steel. But first, let’s differentiate between two copper alloys – brass and…

Read MoreMetalTek offers more metal casting process diversity. Your ability to source centrifugal, sand, investment, HPLT, or continuous cast products from a single company is not available anywhere else in the world. Not sure which precision casting process is right for your components or application? Read the below article on what is casting and its types.…

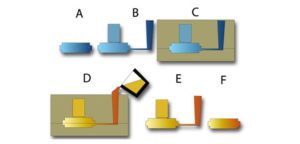

Read MoreSand Casting Sand casting can be traced back to earlier than 1000 B.C. It is widely accepted as the oldest known casting process. The sand-casting process has evolved significantly since the beginning. But the process of how to sand cast has not strayed. The cast molding process is basic, create a cavity in the shape…

Read More