Blog Considerations When Specifying and Purchasing Metal Castings

By: Tim Lulling and Armand Garcia

Metal casting is a complex process that requires numerous considerations when purchasing, including casting design, the metal casting process to be used, and quality control factors. Ultimately, there are many considerations in metal casting and there is no “one size fits all” solution. Therefore, we developed an outline of the various considerations when a customer selects a metal casting solution. Before reviewing important considerations in metal casting, let us review MetalTek’s metal casting processes.

Materials Used by Metal Casting Process

Sand Casting Materials

The sand casting process produces metal components of all sizes and shapes with exterior detail and inner passages using cores (if needed). Almost any alloy can be sand cast. In sand casting the “purchased tool” is a pattern that replicates the part to be cast. Patterns are usually hardwoods, polyurethane, or other durable material. The non-reusable sand mold is created by inserting the pattern into a bed of sand, compressing the sand, and removing the pattern. This leaves a cavity in the shape of the part.

Molten metal is poured into this cavity by a series of hollow pathways called risers and runners. After metal solidification, all previously hollow areas (risers, runners, and the cavity made from the pattern) are solid metal. The risers and runners are removed, leaving a metal part resembling the pattern.

Investment Casting Materials

In investment casting, the tooling is a die with an inner cavity that resembles the part. Wax is injected into this cavity to create a wax pattern. The wax pattern is assembled onto a “tree” with other patterns, which is dipped into a ceramic material to create a shell. The wax pattern is melted away, resulting in a hollow shell into which molten metal is poured.

After solidification, the shell and tree are removed. Relative to other metal casting processes, the final part can have a smoother surface, higher dimensional precision, and thinner walls. This results in cost savings due to lower part weight and less post-cast processing. With investment casting, there is a large selection of alloys during the material selection process.

Centrifugal Casting Materials

With centrifugal casting, the basic tooling is typically a steel die into which molten metal is poured. Dies are rotated around a vertical axis (for “ring” shapes) or a horizontal axis (for “tube” shapes). This metal casting process uses centrifugal force to cause heavier material (metal) to move toward the outside diameter (OD) of the ring, and lighter material (oxides and other impurities) to migrate toward the inside diameter (ID).

The metal will solidify from the OD towards the ID, leaving the purest metal on the outside of the metal casting and pushing the less pure elements toward the center. The ID is machined to remove impurities, leaving a solid ring or tube of the highest casting quality.

Important Considerations When Selecting a Casting Process

Choosing The Right Alloy for the Operating Environment

There are important considerations in casting that customers need to be aware of before choosing the specific metal casting type (centrifugal casting, investment casting, or sand casting). For example, what is the operating environment? Will the component experience high heat? High wear? Both? Will the component need to stand up to corrosion from saltwater?

Once the specific operating environment is defined then the appropriate alloy can be chosen. Alloy selection mirrors environmental factors, as various alloys hold up better in extreme temperature conditions, under high wear, or in corrosive environments. MetalTek metallurgists help customers choose the best alloys for their applications.

Optimizing the Manufacturing Process

Any engineer designing a part has a primary objective for the function of the part in question. This objective is subject to a variety of competing constraints. We have already discussed the operating environment, which helps determine a minimum baseline for the material/metal used.

Optimizing the manufacturing process involves identifying and prioritizing all competing constraints. It is imperative to recognize that these competing constraints typically require the customer and metal casting supplier to determine the optimal balance of cost, quality requirements, and speed to market. The next section provides a deeper look into the primary considerations for each major metal casting process.

Balancing Cost, Quality Requirements, and Speed to Market

Presuming that the geometry, metallurgical requirements, and total quantity of parts validate the use of metal castings, here are some general considerations among MetalTek’s three major metal casting processes:

Sand casting

Sand casting benefits:

- Lower piece price, tool cost, and lead time

- Broad range of geometries, including holes/passages not machinable

- Near-net shape to reduce machining costs

- Minimal size constraints

- Custom metallurgical compositions

Sand casting limitations:

- Dimensional tolerances (per ISO 8062 CT10 to CT12) not typically as tight as investment casting

- Cast thickness of 1/4″ to 3/8″ for limited distances; typically minimum of 1/2″ for larger parts

- Machining required to improve as-cast surface finish (250+ RMS)

- Air-melted alloys

Sand casting best fits:

- Low (single piece) to very high production volume

- Need to eliminate machining and/or fabrication

- Wide range of metallurgical compositions (heat, corrosion, and wear-resistant alloys)

- Use of additive manufacturing/3D printing for sand molds or tooling to reduce cost

- Custom and/or complex geometries

Investment casting

Investment casting benefits:

- Higher metallurgical quality

- Tight dimensional control

- Smoother surface (80-125 RMS)

- Minimal metal waste in casting

- Little or no machining

- Can use with vacuum-melted alloys and air-melted alloys

- Broader range of geometries, including tighter dimensions and tolerances

Investment casting limitations:

- Higher piece price, tool cost, and lead time

- Size limited to 40” cube

Investment casting best fits:

- Medium to very high volume

- Expensive or exotic alloys

- Part weight restrictions (e.g., aerospace applications)

- Extreme heat in operating environment

- Many working surfaces or flow paths

Centrifugal casting

Centrifugal casting benefits:

- Directional solidification provides the highest metallurgical quality and superior machinability

- Minimal or no tooling costs for most tube or ring geometries

- Can cast tubes and machine into multiple ring shapes

- Lower costs and lead times than rolled-ring forgings

- Could utilize sand, investment, or other material molds to increase quality in those geometries

Centrifugal casting limitations:

- Geometries are somewhat limited to rings and tubes (which can limit production lot sizes)

- Used primarily with air-melt alloys, with limited size availability for vacuum alloys.

- Must machine ID (it is the riser for the casting)

- OD usually requires machining to remove “orange-peel” surface.

Centrifugal casting best fits:

- Ring or tube geometries competing against forgings

- Some shaped geometries (extra tooling) where higher metallurgical quality is mandatory

How Does MetalTek Meet Quality Requirements?

MetalTek carefully reviews quality requirements from drawings and specifications prior to accepting an order. We comply with all industry standards for allowable tolerances in the various metal casting processes, documented by all required/agreed-upon certifications. In process, we go one step further to ensure compliance with metallurgical requirements.

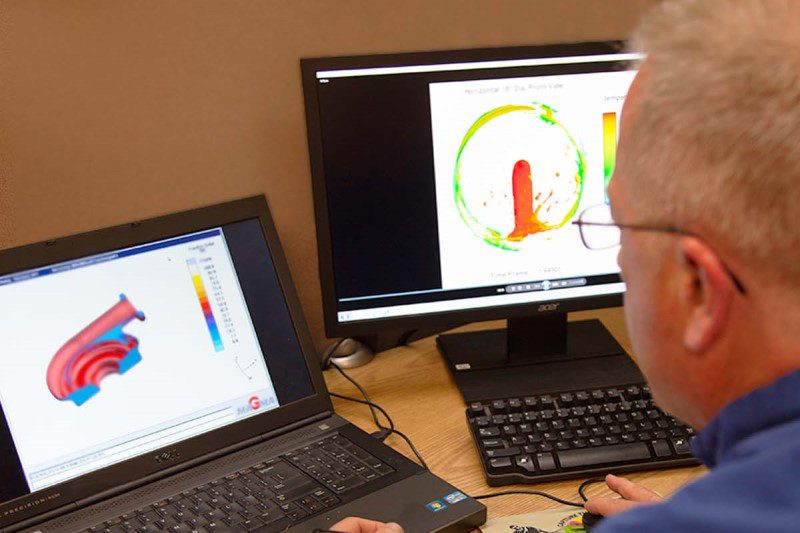

Each MetalTek division uses a solidification modeling program to simulate the flow of molten metal into a mold and analyze the predicted solidification as the mold cools. This model will help in the tool design, including locations for gates and risers, to ensure a metallurgically compliant part.

MetalTek’s Advantages

MetalTek strives to build a collaborative relationship with every customer, to best meet both technical and commercial requirements. The customer’s engineering personnel are the experts in the design of their part, and MetalTek is the expert in alloys and metal casting processes.

We can leverage our wealth of technical expertise and vast industry experience to help your company choose the optimal product design and manufacturing process to meet your objectives.

Contact us and let us help you with your next project.

About the Authors

Tim Lulling is the Western Regional Sales Manager for MetalTek International. He joined MetalTek in 1999 and served in a series of sales roles of increasing responsibility before being named Regional Sales Manager in 2017. Tim holds a BS in Business and an MBA in Materials Management from Arizona State University.

Armand Garcia is Sales Engineer for California, Arizona, and Nevada at MetalTek International. He joined MetalTek in 2014 and has over 25 years of total experience in the foundry industry. Armand holds a BS in Mechanical Engineering Technology from California State University, Sacramento.