Blog Petrochemical Rapid Shutdowns: MetalTek’s Rapid Response Team Again Rises to the Challenge

By: Dale Freihoff

While planned shutdowns are regular occurrences in the life cycle of a petrochemical plant, not all shutdowns are planned. Furnaces can experience unplanned shutdowns. These events are often referred to simply as “shutdowns” but can also be referred to as a “rapid shutdown” (RSD) or “emergency shutdown.”

In the event of a rapid shutdown, a plant owner or operator needs a rapid response from a metal casting supplier. Over a recent long holiday weekend, the team at MetalTek’s Carondelet Division in Pevely, MO once again demonstrated that they have what it takes to be a rapid-response partner for the petrochem industry.

How did Carondelet’s petrochem rapid response team support the customer’s rapid shutdown need?

During a rapid shutdown, time is critical. Lost revenue can literally amount to millions of dollars per day. Carondelet showed it was up to the challenge when responding to the customer’s rapid shutdown request.

MetalTek Petrochemical Field Sales Engineer Dale Freihoff received a call from the customer on the Thursday before a long holiday weekend and was told that a furnace failure had taken place. Despite the upcoming holiday, Carondelet General Manager Shawn Cefalu rallied the team and established the goal to have an official proposal by midday on Monday.

The team at Carondelet responded. Estimating and costing was calculated. Drawings were completed. A round-the-clock production schedule was put in place to ensure onsite delivery within three weeks. It was a true cross-functional effort that included Management, Sales, Engineering, Operations, and other parts of the organization.

By lunch time on Monday, the customer received an official proposal… signed, sealed, and delivered.

Carondelet’s petrochem rapid response team had done its job (while spending the long weekend with their respective families).

How does Carondelet serve the petrochemical industry?

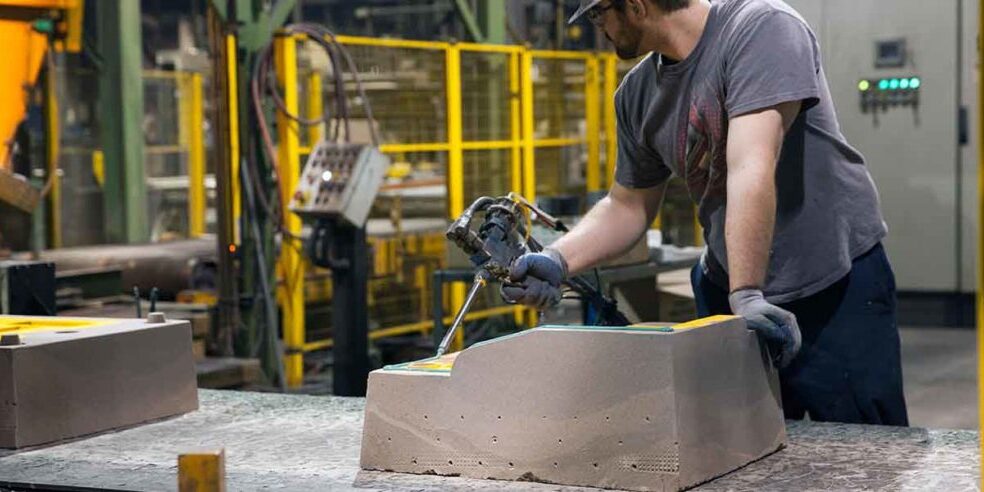

Carondelet is a sand-casting facility that will celebrate its 130th anniversary in 2020. It has a long history of serving of petrochemical customers in applications such as:

- Ammonia production

- Convection and radiant furnaces

- Direct Reduction of Iron (DRI)

- Ethylene production

- Hydrogen production through steam methane reforming (SMR)

- Methanol production through SMR

Petrochemical products offered by Carondelet include:

- Bullhead tees

- Return bends

- Tube sheets

- Ethylene cracker tube fittings

- Wye fittings

Why is MetalTek the best metal casting supplier for rapid shutdowns?

MetalTek is the leader in petrochemical rapid shutdowns due to:

- Decades of petrochem experience serving customers around the world

- Full range of metal casting processes, including sand casting at Carondelet in Pevely, MO and centrifugal casting at Wisconsin Centrifugal in Waukesha, WI

- Deep metallurgical capabilities and a broad selection of heat-resistant alloys

- Complete machining and fabrication capabilities that eliminate the need for a third party

- Shipping capabilities to locations around the world

If a mechanical failure or another factor has caused an unplanned shutdown at your petrochemical plant, give us a call by phone or submit a request for quote through MetalTek.com. Our petrochem rapid response team is always ready for the challenge.