Wisconsin Investcast

Investment castings for high-compliance markets, with unique capability for large parts

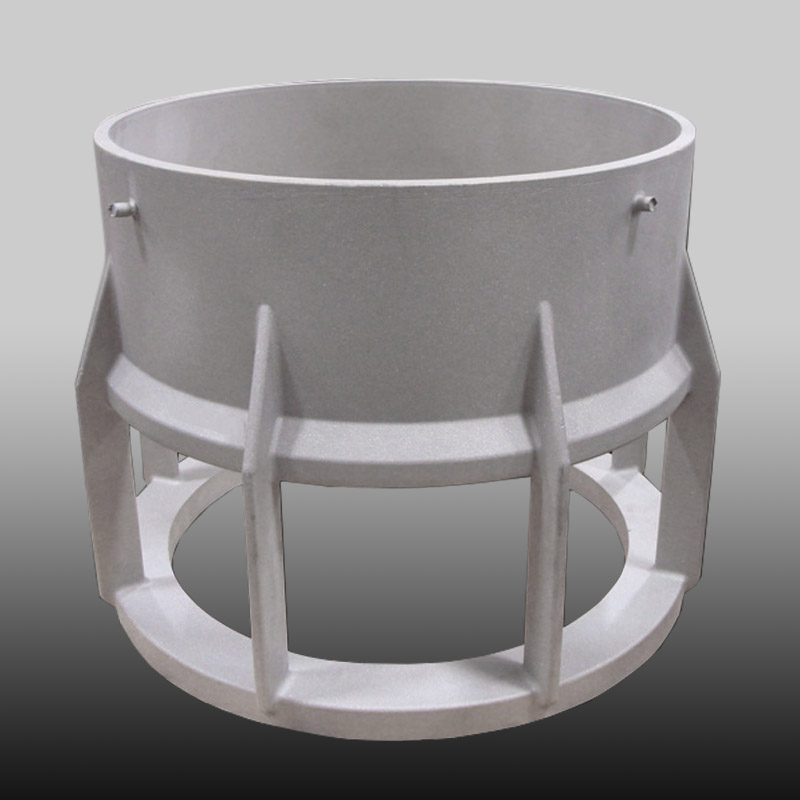

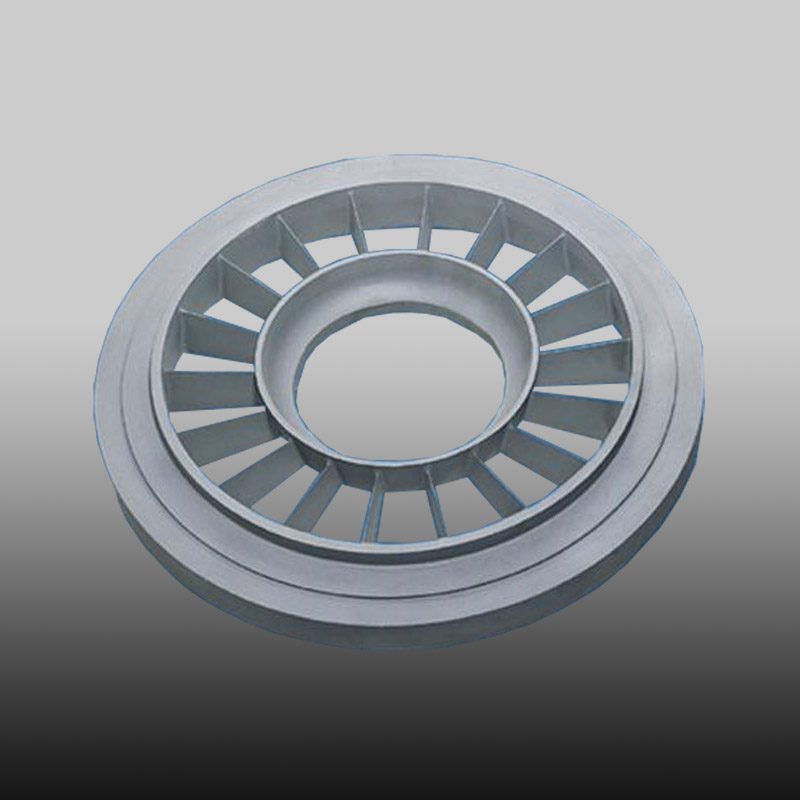

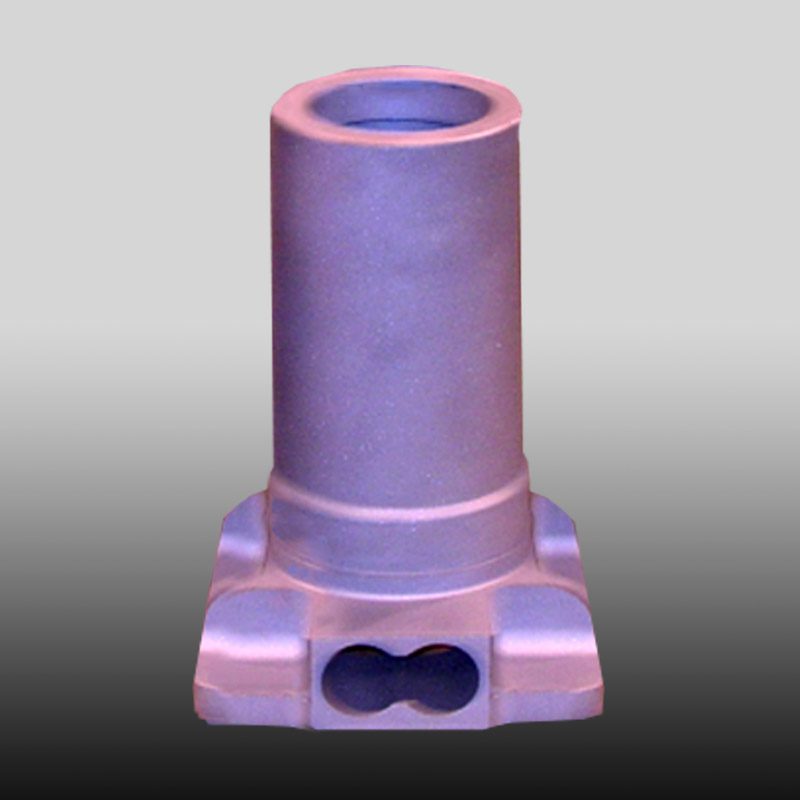

Wisconsin Investcast is an integrated investment casting foundry handling customer component production needs from rapid prototyping, design for manufacturing/casting, tool design and development, solidification modeling, wax pattern production, shell molding, casting, and non-destructive/QA testing. Concurrent engineering services help consider manufacturability during product design to reduce development time and cost. We are known for producing complex metal components in a variety of alloys, and some of the largest investment castings in the world. Whether complex or simple shapes, small to large, we serve a range of high-demand markets such as Defense, Energy, and Turbine Engine.

We can produce investment castings that weigh as little as ounces to large castings up to 2,000 lbs. (635 kg) cast weight and 1,000 lbs. (454 kg) ship weight.

Processes and Capabilities

Investment casting (lost wax casting) is ideal for the manufacture of components with complex internal and external configurations. Net-shaped casting requires little or no post-production machining and is an economical alternative for heavily-machined parts and multi-piece weldments.

Capacities

-

Our induction furnaces offer capacities up to 2,000 lbs (295 kg to 907 kg)

-

Air melt alloys for components with ship weights up to 1,000 lbs. (454 kg)

-

Part envelope size up to 40” diameter by 34" tall (1,016 mm by 864 mm)

We are willing to work with customers to produce castings beyond our standard capacities.

Turnkey Service

We work together with our customers to offer engineering support, casting design for manufacturability, alloy selection assistance, and to identify efficiencies in prototype and production runs. Wisconsin Investcast can provide complete-to-print products with single-source responsibility, including:

-

Heat treatment

-

Hot Isostatic Pressing (HIP)

-

Machining

-

Fabricated assemblies

-

Special surface finishing including pickling, passivation, painting and plating

Rapid prototyping

Additive manufactured / 3D printed patterns and cores using several printing techniques including stereolithography (SLA) and fused filament fabrication (FFF) / fused deposition modeling (FDM).

Solidification modeling

-

ProCast

-

SolidCast

Materials

We routinely pour over 100 alloys, from low carbon through nickel and cobalt based.

-

300 Series Stainless Steel

-

400 Series Stainless Steel

-

Precipitation hardened (PH) grade stainless steels

-

Nickel-base alloys

-

Cobalt-base alloys

-

Heat resistant alloys

-

Carbon and low alloy steels

In addition to standard alloys, MetalTek regularly works with customers to modify grades to deliver the performance needed for a particular application and environment. For more information on MetalTek alloy capabilities, visit our alloy guide.

Non-Destructive Testing

-

Radiography / X-Ray testing (RT)

-

Fluorescent penetrant inspection (FPI)

-

Magnetic particle inspection (MPI)

Accreditations and Certifications

Our quality personnel manage a broad range of internally and nationally certified test functions and programs including:

-

ISO 9001:2015 (QMS)

-

AS9100D (QMS)

-

MIL-I-45208

-

Nadcap (weld upgrade, X-Ray, FPI)

-

Numerous customer-specific approvals

contact us

To contact Wisconsin Investcast Division please call 1-920-261-2114.

WISCONSIN INVESTCAST

661 South Twelfth Street

Watertown, WI 53094

PH: 1.920.261.2114

FX: 1.920.261.5663

Find your sales engineer for Wisconsin Investcast.

Solutions

- « Previous

- 1

- 2