Direct Reduction of Iron (DRI)

North America's Leading Supplier of DRI Reformer Tubes

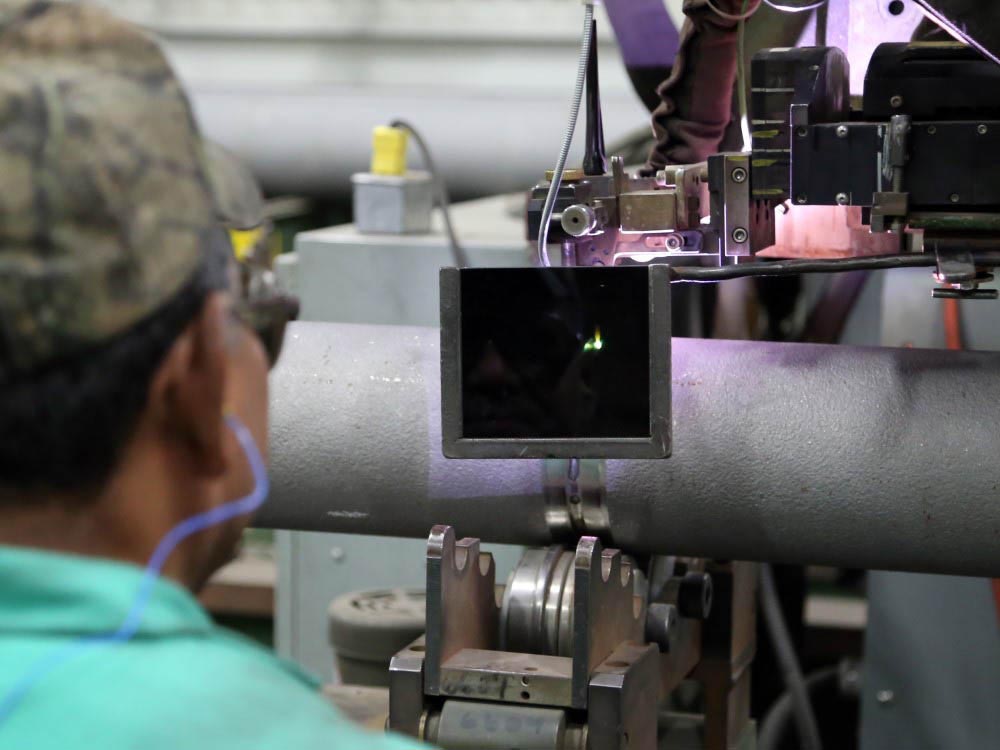

MetalTek is North America's leading supplier of centrifugally cast reformer tubes for the direct reduction of iron (DRI). DRI is the process of producing metallic iron by removing oxygen from iron ore without melting. During DRI reformer tubes produce hydrogen, which reacts with the iron ore inside a heated furnace and removes the oxygen. The process results in either direct reduced iron or hot briquetted iron, either of which are subsequently melted to produce steel.

Extend Reformer Tube Life and Lower Life cycle Costs

MetalTek's strict metallurgical and manufacturing process control results in extended reformer tube service life and lower life cycle costs for DRI providers.

-

Alloys such as MTEK 25-35MA, MTEK 30-50W, and the proprietary MTEK MA-1 offer a balance of creep rupture strength, thermal fatigue strength, and oxidation and carburization resistance. This provides customers with the exact material properties that they need.

-

Wisconsin Centrifugal performs engineering, casting, machining, fabricating, and testing on site. Our DRI reformer tubes meet exact customer specifications for operating temperature, tube wall thickness, and concentricity.

To learn more, contact us, find a Petrochemical Key Account Manager, or consider a TekSession.

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.