Blog Domestic Sourcing vs. International Sourcing of Metal Castings

By: Robb Edwards

When a North American manufacturer considers where to source metal castings, the choice typically involves domestic sourcing (North America) versus international sourcing (outside North America). There are several considerations when making this decision as a customer. These considerations can range from cost to the overall nature of the supplier relationship. The choice is not typically “black and white.”

Sometimes there is a blend of domestic and international sourcing options for metal castings that is a customer’s best-case solution. Below we review the general benefits of both domestic and international sourcing of metal castings. We then detail specific considerations when making the choice.

Benefits of Domestic Sourcing and International Sourcing of Metal Castings

Benefits of Domestic Sourcing of Metal Castings

If sourcing metal castings from a domestic (North American) supplier, a customer quickly realizes a few key benefits. The first benefit is a close cultural and geographic relationship with its metal casting supplier. With limited language and time zone differences, problems can be resolved quickly. Additionally, quality inspection standards can be much more rigorous in North America compared to other parts of the world. Customers know that quality inspections are performed in house to the highest available standards.

MetalTek welcomes potential customers to visit any of its locations and discuss project needs. Partnering on future metal casting projects is easier after building a trusted local relationship and having a candid technical and commercial dialogue. From the first contact with a potential customer, MetalTek focuses on getting to know the customer first, then the project.

Benefits of International Sourcing of Metal Castings

Companies choosing castings from international sources are often multinationals. With sites around the world, multinationals can essentially source locally, and utilize their local employees to manage the supply chain. Additionally, there are domestic companies that are not multinationals that go this route.

The benefit that many pursue when sourcing internationally is perceived lower costs, the perception driven by low labor rates. Metal commodity prices should be consistent globally, and materials from international suppliers can certainly be affected by tariffs and subsidies. Hence, a measured approach should be taken.

Labor costs are typically lower from international metal casting suppliers and can provide effective cost savings, where labor is a significant component of the domestic casting cost. A good time to source internationally can be for bulk orders of castings with more labor content, coupled with a limited need for strict quality testing.

Domestic vs. International Sourcing of Metal Castings: Specific Considerations

There is no one-size-fits-all solution for customers when choosing between domestic and international sourcing for metal castings. In fact, the decision process is often an ongoing cost-benefit analysis. Below are specific considerations to help customers make the best choice for their needs.

Communication:

Planning the production of complex metal castings and troubleshooting ongoing issues with an international supplier can present challenges compared to a domestic supplier. Efficient communication is paramount when resolving prototype, first article sample, and production issues as quickly as possible.

Language barriers and time zone differences only add to the complexity of the international sourcing process. A benefit of a domestic source of metal castings is real-time communication and prompt resolution of production issues.

Cost Savings:

Another critical difference between domestic and international suppliers of metal castings is cost. Raw materials generally yield consistent pricing from both domestic and international suppliers, but government subsidies and tariffs do have an impact. Domestic supplier labor costs will almost always be higher, but logistics costs will be lower, due to less distance the casting must travel.

Higher logistics costs from international suppliers can be expected, and there is potential that customers will periodically be required to airfreight parts. This should not be overlooked. Supply chain issues such as backlogged ports, fuel surcharges, and overall transportation costs can dramatically increase the overall cost. A good “rule of thumb” is that unless cost savings of international sourcing are projected at 25% or more, domestic sourcing is the better choice.

Source Location:

Another consideration is the actual sourcing of the materials. It is usually preferential to source materials locally. Considering supplier relationship management, logistics, and raw material costs most companies regardless of location prefer to source as locally as possible to the foundry. Overall, there is less risk, currency fluctuation costs are mitigated, and you’re dealing with a supplier in a close time zone.

Appetite for Risk:

The last major consideration is an appetite for risk. Customers must always be vigilant about anticipating changes when working with international suppliers of metal castings. Such changes can be production delays, quality problems, air freight, and the cost to its business if the part is not delivered on time. With domestic suppliers of metal castings, these risks can be greatly reduced. In addition, intellectual property laws vary dramatically by country. Can a customer afford to have its intellectual property at risk?

If there is tolerance for some risk, a blend of domestic and international sources of metal castings can be the optimal fit for the customer. For example, projects with straightforward requirements and large quantities can be excellent for international sources. The domestic source can be utilized for a smaller portion of the base demand and be ramped up quickly to address periods of peak demand. The customer receives the benefit of an overall lower spend on castings and can leverage the domestic capacity for peak demand.

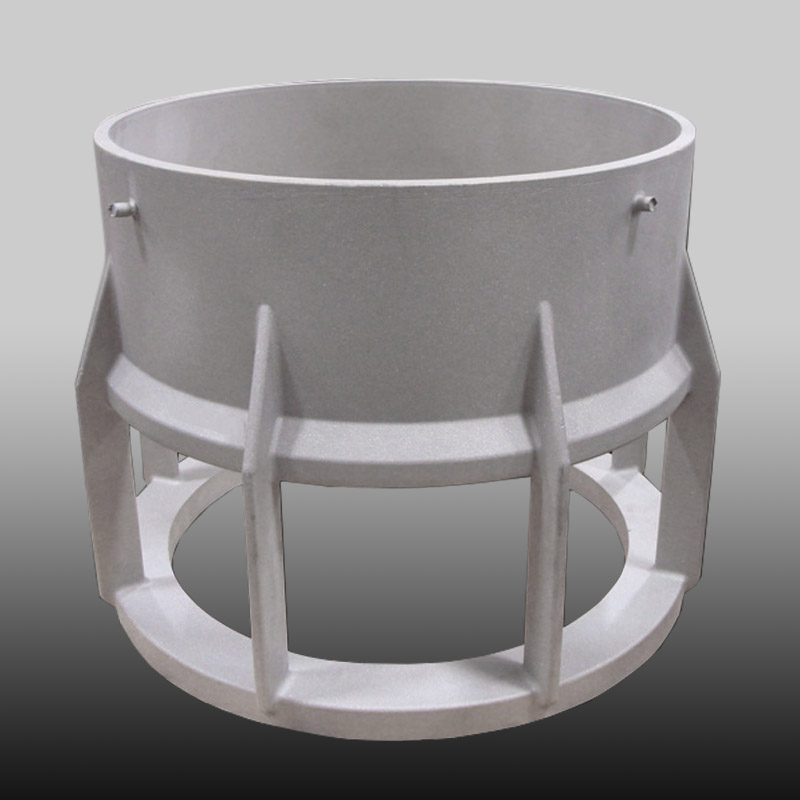

Projects involving castings with more complex geometry and more stringent quality requirements including non-destructive testing (e.g., die penetrant, radiographic testing) are likely better suited for domestic sources, where training and certifications of staff are higher confidence.

Conclusion:

Whether your company ultimately decides on a domestic or international source for metal castings, there are a few key concepts to remember. Domestic sources generally have less logistical risk, more efficient communication, and fewer barriers to overcome. With international sources, perceived upfront savings on labor costs can be outweighed by logistical and supply chain costs, inefficient communication, and inconsistent quality standards.

Developing a collaborative and consultative relationship with a metal casting supplier is by far the most important consideration in a customer’s decision. Every project has unique challenges and trusting the metal casting supplier from the onset is critical.

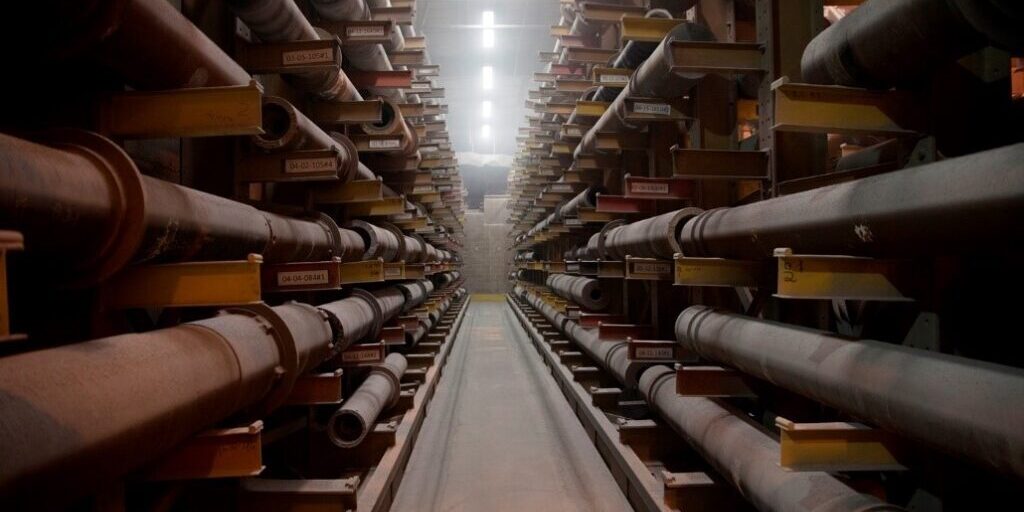

At MetalTek we set expectations, establish clear metrics, and provide on-site value-added processes including mechanical testing, non-destructive testing, heat treating, and machining on our castings. We expect open lines of communication with our customers, whether we encounter challenges or are simply providing project updates. Domestic and international sources both provide advantages and disadvantages, but MetalTek can help provide the solution that best fits your unique project.

Contact us to learn more about how we can help.