Blog What Is Low Alloy Steel?

By: Tyson Wolfe

What Is Low Alloy Steel?

In general, there are two categories of steel:

- Low alloy steel

- Stainless steel (or high-alloy steel)

Low alloy steel has low percentages of alloying elements such as chromium and nickel compared to stainless steel. As a result, low alloy steel does not have the heat, wear, or corrosion resistance provided by stainless steel. However, low alloy steel provides exceptional mechanical properties and a relatively low cost which makes it desirable for numerous customer applications.

The sections below detail why low alloy steel should be used and describe a few of the applications where MetalTek uses low alloy steel to manufacture components for its customers.

Why Use Low Alloy Steel?

Specific advantages provided by low alloy steel are:

- Low cost

- High strength

- Versatile mechanical properties

- Good weldability

Common examples of low alloy steel are:

- 4130 low alloy steel

- 4140 low alloy steel

- 4340 low alloy steel

Each of these (in addition to other low alloy steel) have the cost, strength, mechanical property, and weldability advantages described in detail below.

Low Cost

Because of the fewer alloying elements, low alloy steel such as 8620 has a lower cost and higher strength compared to stainless steel alloys such as MTEK 625 or MTEK 25-35. These stainless alloys, with higher chromium and nickel, achieve corrosion and heat resistance, but have a higher overall cost than low alloy steel. Low alloy steel can be a great choice for applications where cost savings and physical properties such as high strength are more critical than heat or corrosion resistance.

High Strength, Low Alloy Steel (HSLA)

Another advantage that low alloy steel has is strength. Low alloy steel can provide outstanding strength, even stronger than many high-strength martensitic stainless steel such as MTEK M-152 (which also provides excellent corrosion resistance). This can make low alloy steel ideal for high strength applications where properties such as corrosion resistance are not critical.

Versatile Mechanical Properties

Low alloy steel can achieve a wide variety of mechanical properties. The versatility of low alloy steel allows it to meet the strength requirements for applications ranging from structural steel to mining to unique customer applications. The versatility of mechanical properties of low alloy steel is yet another reason it is found in so many applications for so many industries.

Weldability

Low alloy steel has excellent weldability. This makes it appealing for applications such as defense that have welded assemblies and fabrications.

Low Alloy Steel: Application Examples

There are prominent examples where the low cost, high strength, versatile mechanical properties, and high weldability of low alloy steel make it ideal for specific customer applications:

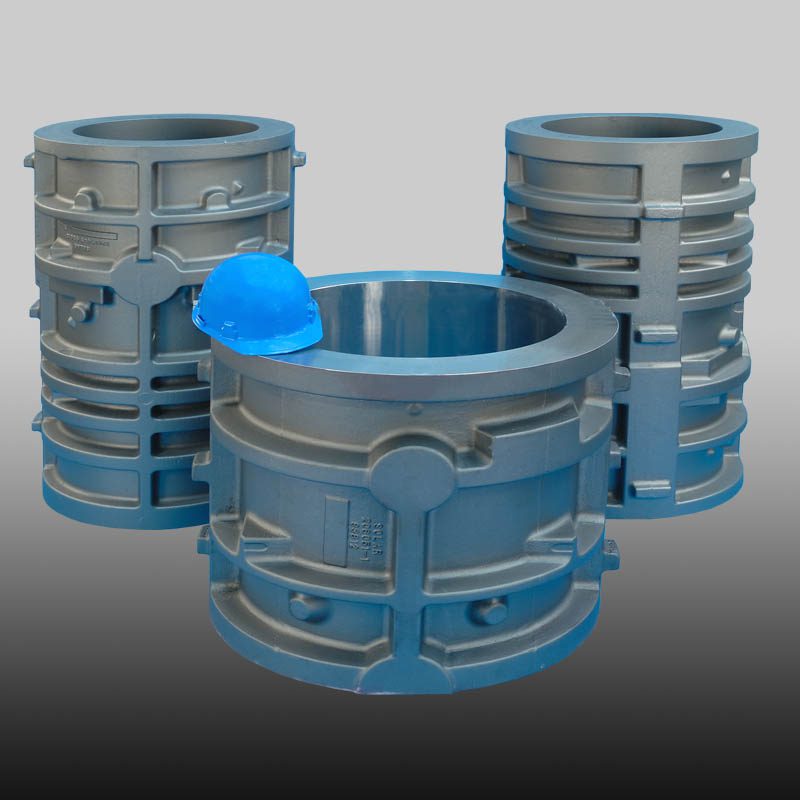

- Power generation: MetalTek centrifugally casts engine cases for land-based turbine engine applications in a low alloy steel (MetalTek grade WC 6).

- Defense: MetalTek produces centrifugally cast and investment cast components for a proprietary artillery application for the U.S. military. The low alloy steel used for this application provides excellent strength as well as good weldability with other components in the complete assembly.

- Mining: Hydraulic cylinders made from MTEK 8630 require excellent strength to help support mining dump trucks, which can weigh hundreds of tons when fully loaded.

Low Alloy Steel: Conclusions

Low alloy steel has advantages that make it ideal for a range of customer applications where high strength and low cost are paramount. MetalTek has practical expertise in over 450 ferrous and non-ferrous alloys, including proprietary grades. This expertise allows customers to choose alloys that meet the most demanding product requirements. Contact us to learn more.

About The Author

Tyson Wolfe is a Metallurgical Engineer at MetalTek’s Wisconsin Centrifugal Division. He joined MetalTek in 2019 with previous metallurgy and foundry experience. Tyson holds a BS in Materials Science and Engineering from the University of Wisconsin – Madison.