Ethylene Cracking

Ethylene cracking coil, cracking tubes, and Related Components

Ethylene steam cracking (also known as pyrolysis) coverts hydrocarbons such as ethane and propane into less complex hydrocarbons such as ethylene and propylene. These are the raw materials of plastics and other critical products. During the ethylene cracking process, the ethylene cracking coil containing the feedstock and steam is heated inside a furnace to temperatures approaching 2,000°F (about 1,100°C), “cracking” the feedstock into its simpler forms.

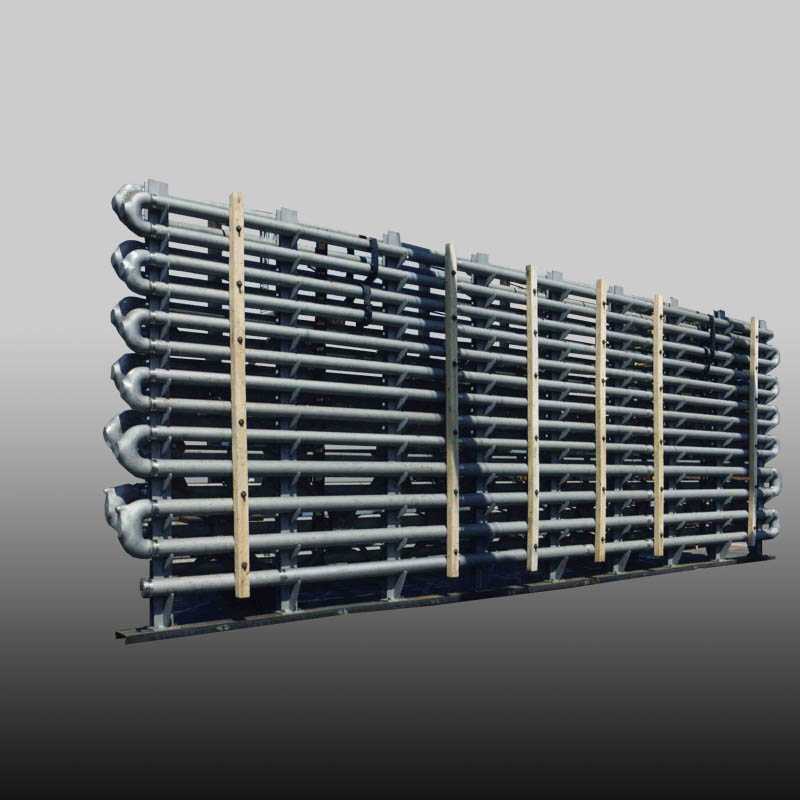

The cracking tubes and fittings that make up the cracking coil must operate in this high-temperature environment for several years with limited downtime. MetalTek manufactures centrifugally cast cracking tubes at Wisconsin Centrifugal and sand cast fittings and tube sheets at Carondelet. Wisconsin Centrifugal fabricates, tests, and ships complete ethylene cracking coil assemblies directly to customers.

Extend Cracking Coil Life And Decrease Downtime

MetalTek has served ethylene producers with cracking tubes, fittings, tube sheets, and complete cracking coil for decades. Our strict metallurgical and manufacturing process control allows us to provide:

-

Consultative customer relationships based on using our extensive market knowledge to understand and anticipate their specific needs

-

Industry-leading lead times and on-time delivery, with expedited delivery when required

-

Traditional alloys that provide reliability and excellent value

-

Alumina forming alloys that improve efficiency, reduce downtime, and extend ethylene cracking coil life through increased resistance to coking and carburization

To learn more, contact us, find a Petrochemical Key Account Manager, or consider a TekSession.

Need help with a new project?

Let's push the limits of what is possible, together. Ask your metal experts.

Solutions

Ethylene Cracking Tubes

MetalTek’s strict metallurgical and manufacturing process control results in centrifugally cast ethylene cracking tubes that resist coking and carburization.

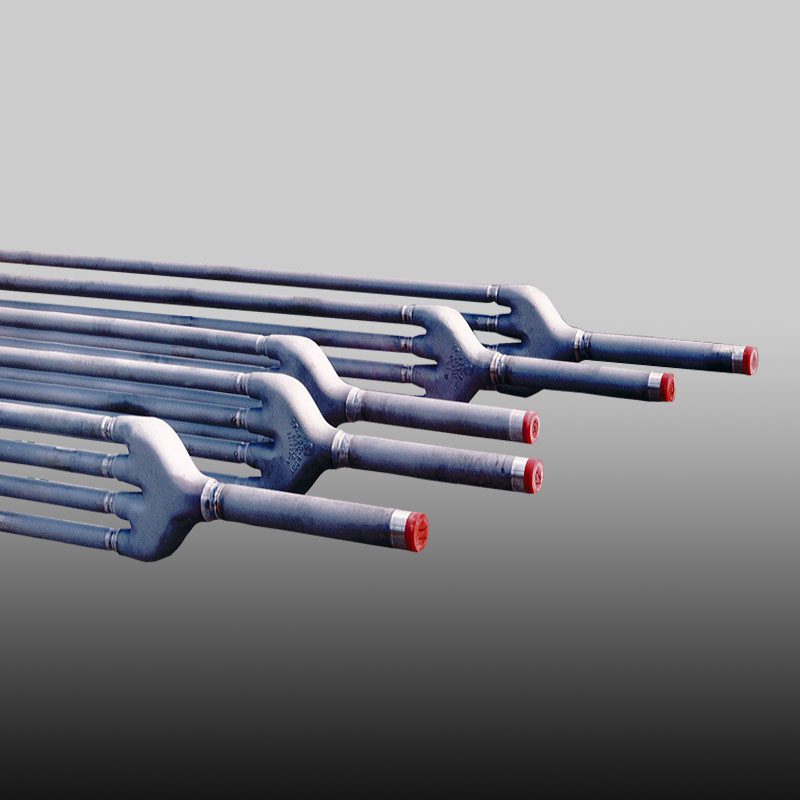

Petrochemical Fittings – The Full Range

MetalTek manufactures a full range of petrochemical fittings.