Blog

From the desk of Your Metal Experts...

Welcome to the MetalTek blog.

MetalTek uses our integrated alloy and process expertise to help customers make their products perform better in the world's most demanding applications. Please browse the blog topics displayed below to find a topic of interest to you.

For more information about a specific alloy or manufacturing process, contact us or consider a TekSession. You can also browse our hundreds of available alloys for the material properties that best fit your application.

Search

Topics

8 Metals Commonly Used For Casting

Metal casting involves pouring molten metal into a die or mold to form a desired shape. Numerous types...

MetalTek’s Carondelet Division Certified to Produce HY-80 Steel

MetalTek's Carondelet Division is excited to announce that we achieved certification to produce HY-80 steel. HY-80 is a...

Investment Casting Misconceptions

Investment casting has many benefits over other casting processes. Ranging from cost savings (reduced machining costs and material...

Bearium Metal Alloys: An in-depth guide of proprietary leaded bronzes

What Is Bearium Metal? Bearium Metal is a group of high lead tin bronze alloys containing virgin copper,...

Sandusky International: Largest Centrifugal Castings for Demanding Industries Worldwide

MetalTek’s Sandusky International Division is a leading supplier of large metal components for high-heat, high-wear, and high-corrosion applications...

Types Of Wax Used In The Investment Casting Process

Investment casting, also known as lost wax casting, is a metal casting method for shaping metal parts that...

3 Common Types of Sand Used in Sand Casting

Sand casting is a versatile and cost-effective solution for the creation of metal parts. In fact, most metal...

How To Choose a Metal Casting Supplier for the Petrochemical Industry

Planned turnarounds are regular occurrences in the life cycle of a petrochemical plant. Every few years, a plant...

304 vs. 316 Stainless Steel: Which One Is Better?

Stainless steel is one of the world's leading metals in various applications. It provides exceptional corrosion resistance, durability,...

Will Aluminum Rust or Corrode?

Aluminum does not rust but it can corrode. What is the difference between rust and corrosion? Rust and...

The 101 On Thermal Conductivity In Metal Alloys

One crucial property to understand in metalworking is thermal conductivity. The simplest definition of thermal conductivity is a...

A Guide to Different Types of Bronze Alloys

Introduction Bronze is a copper-based alloy that has been valued throughout history for its versatility, durability, and attractive...

Comparing Costs for Investment Casting, Sand Casting, and Centrifugal Casting

When considering the production of complex metal components, it is important to evaluate the costs associated with different...

Experiencing Supply Chain Issues With Your Current Investment Casting Supplier?

Are you experiencing supply chain issues with your current metal manufacturing vendors? In today’s marketplace, long lead times,...

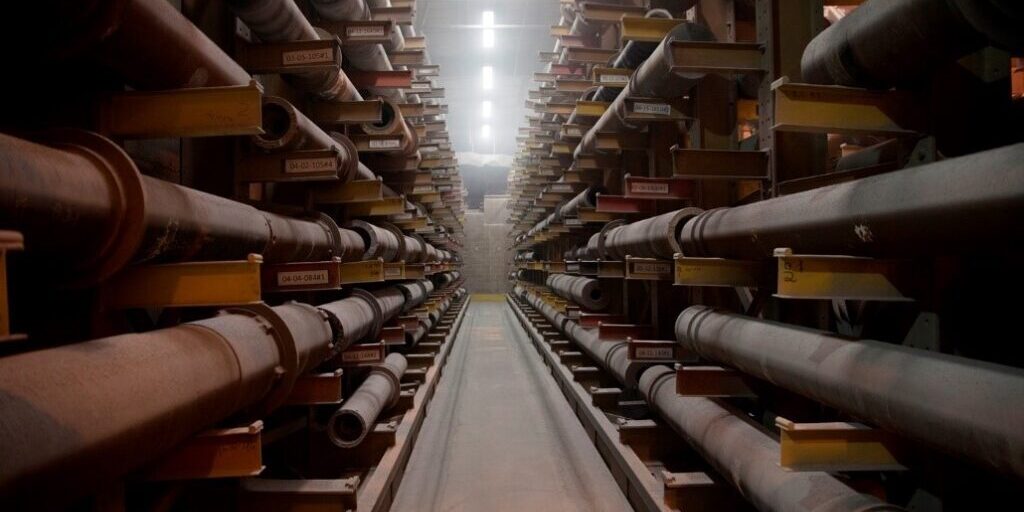

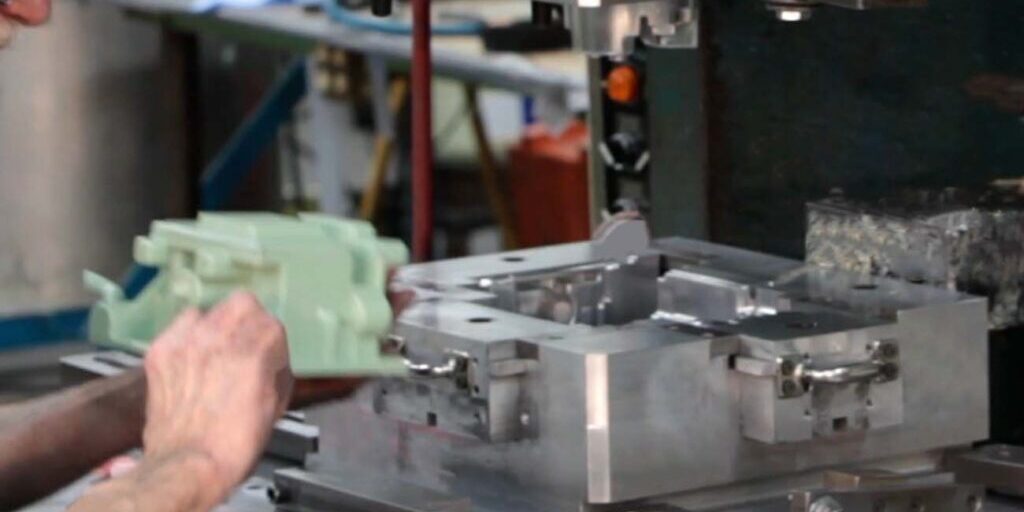

Tooling for Investment Casting: What Is The Process and How Does It Work?

Investment casting (also known as lost-wax casting) is a common manufacturing process used to create metal parts with...

What Is Low Alloy Steel?

What Is Low Alloy Steel? In general, there are two categories of steel: Low alloy steel Stainless steel...